La experiencia y la innovación en Investigación y Desarrollo de Reading Bakery Systems (RBS) así como nuestra gama de equipos industriales para la producción de galletas saladas son insuperables en la industria de equipos de panadería comercial.

Con sede en Robesonia, Pensilvania, RBS atiende a fabricantes de aperitivos en todo el mundo, especializándose en una amplia gama de equipos para mezclar, manipular y formar masa, así como en equipos de horneado, secado y complementarios. Nuestros productos ayudan a los clientes a superar los desafíos de producción de galletas saladas.

Nuestros sistemas de línea de producción son duraderos y confiables, ideales para procesar masa de galletas saladas fermentada o no fermentada, así como masa de galletas y otros productos de masa de dos etapas o fermentados.

Mezclado Continuo para Crackers

RBS recientemente ha desarrollado el Mezclado Continuo para la industria de las crackers. La mezcladora Exact EX Continuous Mixer brinda varias ventajas sobre la mezcla por lotes, incluyendo:

- Proceso completamente automatizado

- Libre de variaciones no deseadas de lote a lote

- Peso, tamaño y textura final consistentes

- Hidratación uniforme de la masa

- Control de receta y repetibilidad

- Elimina posibilidades de contaminación

- Requiere menor mano de obra y energía que el mezclado por lotes

- Altas tasas de producción con un solo mezclador

La mezcladora EX Continuous Mixer trabaja uniformemente los productos con una variedad de niveles de humedad en la masa, reduce el tiempo de reposo, elimina las canaletas de masa y reduce la mano de obra y la energía gracias a la automatización completa. Ofrece tasas de producción de masa de 100 a 10,000 kg/hora.

Laminado

La laminadora 2-roll, 3-roll, o 4-Roll produce láminas libres de hoyos, con una densidad uniforme, lo cual es crítico para los sistemas de empaque automatizados después del horno. El grosor de la lámina se controla mediante la distancia entre los rodillos, misma que es ajustable. Los rodillos comprimen la masa en una sola lámina con características y grosor consistentes.

Considere la laminadora Servo-Cut Sheet Thomas L. Green o la In-Line Laminator para cortar, apilar y entregar hojas de masa con precisión para realizar texturas de producto únicas. La colocación precisa y suave de las hojas cortadas proporciona una densidad de masa uniforme en los bordes y en el centro de la hoja de galleta terminada, garantizando consistencia. Las laminadoras de masa pueden instalarse al lado o directamente encima de la laminadora para obtener un diseño de producción compacto y eficiente.

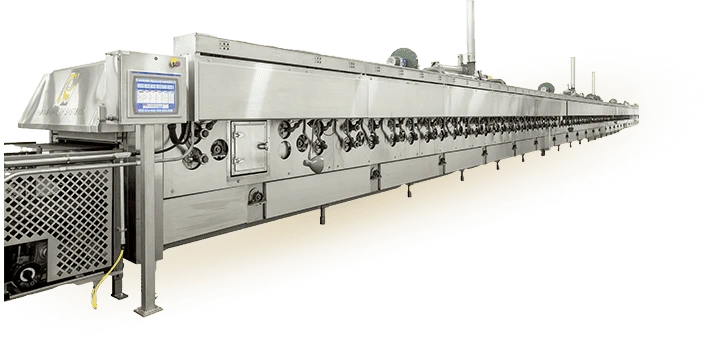

Horneado Consistente

El Thomas L. Green PRISM OVEN es ideal para la producción de crackers y bizcochos con una plataforma de horneado de paso único diseñada para ofrecer calidad, color, sabor y textura uniformes. Ofrece zonas de horneado directo a gas, convección y emitermica (radiante/convección).

Cuando busque consistencia en sus galletas, aproveche la tecnología de “cocción” directa a gas en la zona de horneado para eliminar la humedad y controlar el color, mientras que en la zona de convección. Los clientes enfocados en la calidad, aprecian el PRISM OVEN por el control repetible de temperatura, tiempo, humedad y tipo de transferencia de calor.

Productos Relacionados

Los sistemas completos RBS para crackers incluyen Estaciones de Calibración para asegurar una gentil reducción en el grosor de la lámina previa cortar las formas en la estación de corte Rotary Cutting Station. Un Cracker Breaker también está disponible para dividir con precisión las hojas de galletas dentadas.

Los toppings de todo tipo se pueden distribuir fácilmente con uno de nuestros Omega Dispensers que pueden manejar una amplia variedad de materiales de topping, las trituradoras de granos finos y granos irregulares tienen mecanismos de nivelación que reducen al mínimo la formación de puentes y aglomeraciones de material.

Los panaderos de galletas saladas de todo el mundo han confiado en los equipos de Reading Bakery Systems y Thomas L. Green durante más de un siglo. Si está interesado en producir las mejores galletas saladas de la industria, comuníquese con nosotros a los números que se muestran a continuación para explorar nuestra amplia gama de equipos para la producción de galletas saladas.

- América del Norte: +1 610-693-5816

- América Latina: +57 316 672 8560

- Europa: +31 615-510-789

- China: +65 8782 1066

- Medio Oriente / África: +971-56-6787885

- Asia Sudoriental: +65 8479 4490