Labor is one of the biggest line items in any bakery, and it’s also the most personal. People bring skill, judgment, and pride to every shift. The question isn’t how to replace them – it’s how to help the team spend time where it matters. At Reading Bakery Systems, we build continuous mixing solutions that turn a lot of the stop-and-start batch work into a steady, predictable flow. The result is fewer hands tied up with repetitive tasks and more attention available for quality and throughput. Can continuous mixing lower labor costs in bakeries? You bet. Here are some reasons why.

Labor is one of the biggest line items in any bakery, and it’s also the most personal. People bring skill, judgment, and pride to every shift. The question isn’t how to replace them – it’s how to help the team spend time where it matters. At Reading Bakery Systems, we build continuous mixing solutions that turn a lot of the stop-and-start batch work into a steady, predictable flow. The result is fewer hands tied up with repetitive tasks and more attention available for quality and throughput. Can continuous mixing lower labor costs in bakeries? You bet. Here are some reasons why.

Why Batch Mixing Demands So Much Labor

Traditional batch rooms can feel like a carousel: weigh, load, mix, unload, clean, and repeat. Each step invites delays and rework. When a batch runs long or lands a little off, operators hustle to correct it, and that ripple reaches forming and baking. It’s a lot of manual oversight, plenty of lifting and staging, and too many chances for small inconsistencies to become shift-long headaches. Even the best teams spend valuable minutes waiting for the next batch to be ready.

How Continuous Mixing Changes The Labor Math

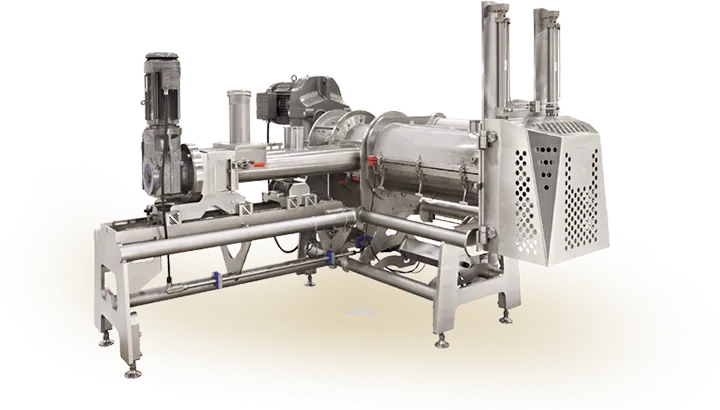

Continuous mixing creates a stable stream of dough that’s mixed as ingredients are metered in. Instead of loading and unloading bowls, your crew watches a process that runs – calmly – at a set rate. With our Exact Mixing solutions, we design systems to meter dry and liquid ingredients automatically, blend them uniformly, and deliver dough directly to downstream equipment. That means fewer manual touches, fewer trips back and forth, and less time spent “fixing” dough before it moves on. You’re not removing people; you’re removing the busywork that keeps people from leading the line.

Fewer Surprises, Less Scramble

Consistency isn’t just a quality benefit; it’s a labor benefit. A steady dough stream helps forming stabilize faster and keeps operators from making constant micro-adjustments. When the dough behaves the same way hour after hour, your best people can step away from firefighting and focus on coaching, sanitation checks, and quick wins that lift first-pass yield. Our controls help you save recipes and set ranges so your team can see what “good” looks like at a glance and make confident, quick calls.

Training That Sticks

New hires shouldn’t need a crash course in crisis management. Continuous mixing makes onboarding feel less like learning a hundred exceptions and more like learning a few reliable routines. We support teams with plain-language SOPs, visual standards, and straightforward setpoints. Because the process is repeatable, operators gain confidence faster and cross-train more easily. That flexibility reduces the pressure to overstaff every shift and makes scheduling simpler when people take time off.

Cleaner Work, Quicker Changeovers

Labor hours aren’t just spent making product – they’re also spent preparing to make product. Continuous systems help by reducing dust from bag dumping, minimizing sticky buildup, and streamlining cleanup. With fewer bowls and less mess, changeovers move faster and sanitation feels more manageable. You’ll spend less labor resetting the room and more time running on spec. Our engineering teams design for access and cleanability so your sanitation crew can do a thorough job without losing half a shift to teardown.

These just scratch the surface of the many reasons why the answer to the question of “Can continuous mixing lower labor costs in bakeries?” is “Yes.” Learn more by calling Reading Bakery Systems at 610-693-5816 or using our online contact form.