Even when your recipes are dialed in and your team is doing everything right, it can feel like you are paying extra just to keep the plant running at full pace. So, can continuous mixing reduce energy use in bakeries? Yes. When you replace a batch cycle with a steady process, you can cut waste that comes from waiting, rework, and inefficient use of downstream equipment. At Reading Bakery Systems, we build continuous mixing systems that help bakeries run more smoothly, and that smoother flow can translate into real energy savings.

Even when your recipes are dialed in and your team is doing everything right, it can feel like you are paying extra just to keep the plant running at full pace. So, can continuous mixing reduce energy use in bakeries? Yes. When you replace a batch cycle with a steady process, you can cut waste that comes from waiting, rework, and inefficient use of downstream equipment. At Reading Bakery Systems, we build continuous mixing systems that help bakeries run more smoothly, and that smoother flow can translate into real energy savings.

Less Rework Means Less Power Burned

Rework is expensive in ways that are easy to miss. When dough comes out inconsistent, your team may try to correct it with extra mix time, adjustments, or even scrapping product and starting over. Every one of those fixes uses energy. You are powering mixers longer, running makeup equipment longer, and sometimes baking product that will not meet spec.

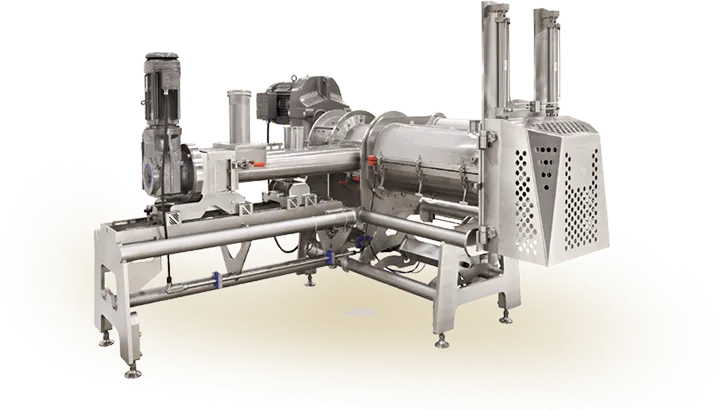

Our Exact Mixing continuous mixer systems are built to help bakeries hold a more consistent mixing process through controlled ingredient delivery and repeatable mixing action. When the dough is more consistent, you can spend less time correcting and more time producing. That reduction in rework does not just save ingredients. It reduces the energy tied to extra mixing time and extra runtime across the line.

Faster Hydration Can Support Energy Savings

Some of the energy cost in mixing is tied to how long you need equipment to run to get ingredients to come together the way you want. If hydration is slow or uneven, it can push you toward longer mixing and more corrections. That is one reason we offer Hydrobond technology for rapid hydration in continuous mixing. The idea is straightforward: bring ingredients together quickly and consistently so the process can keep moving without extra effort.

When hydration and blending happen more efficiently, you can often reduce the need for extended mixing time. You can also reduce the ripple effects that come from dough that needs extra attention.

A Continuous Process Helps Downstream Equipment Run More Efficiently

Mixing is upstream. That means it sets the tone for everything that follows. When mixing output is uneven, downstream equipment has to compensate. Lines may slow down, then speed up. Proofing can become less predictable. Ovens may run underfilled for stretches, then get slammed later as the team tries to catch up. Those swings are not just stressful. They waste energy.

Continuous mixing supports a calmer, more predictable feed to the rest of the process. With our continuous mixer models, we can match the mixing approach to the product you’re making so the line stays more stable. A steadier line often means fewer speed changes and fewer idle periods, which is exactly the kind of operational improvement that can help energy use trend down.

Making Efficiency Easier to Reach

Energy reduction rarely comes from one magic piece of equipment. It comes from a process that works together. We support complete mixing solutions. That matters because inconsistent ingredient delivery can undermine any mixing approach, and patchwork systems can create inefficiencies that show up as downtime and waste. When the system is designed to run as one coordinated process, you can run more predictably. Predictable production is where efficiency lives.

Can continuous mixing reduce energy use in bakeries? Without a doubt, as long as you turn to Reading Bakery Systems products. Learn more by using our online contact form or calling 610-693-5816.