If you’re chasing more throughput but don’t want to gamble with texture, color, or consistency, continuous mixing is the practical next step. Can continuous mixing speed up production without affecting product quality? You bet – as long as you choose Exact Mixing equipment from Reading Bakery Systems. Instead of stopping and starting for each batch, ingredients flow steadily into the mixer, and finished dough flows out at the same pace. That simple shift removes a lot of waiting, reduces handling, and helps every downstream step run more smoothly.

If you’re chasing more throughput but don’t want to gamble with texture, color, or consistency, continuous mixing is the practical next step. Can continuous mixing speed up production without affecting product quality? You bet – as long as you choose Exact Mixing equipment from Reading Bakery Systems. Instead of stopping and starting for each batch, ingredients flow steadily into the mixer, and finished dough flows out at the same pace. That simple shift removes a lot of waiting, reduces handling, and helps every downstream step run more smoothly.

Why Continuous Mixing Speeds Things Up

Batch changeovers add minutes that quietly turn into hours over a week. With continuous mixing, you keep the line moving: dry and liquid streams are metered on spec, dough development happens at a steady state, and you eliminate the empty-hopper moments that slow sheeters and laminators.

When we pair an Exact Continuous Mixer with Hydrobond Technology, we also speed up hydration before the dough enters the mixing chamber. That faster, more even wet-out shortens the time to target development, which helps you hit the same output with less total mixer time. In real plants, that’s more finished product per shift without reworking schedules.

Keeping Quality Locked In

Going faster only matters if the product still eats the way customers expect. Continuous systems help by holding key variables steady: ingredient ratios, dough temperature, and mechanical energy. Because the process is constant, you don’t see the “first-batch/last-batch” drift that can show up with stops and starts.

Hydrobond’s instant, uniform hydration supports even gluten development and reduces pockets of dry or over-worked dough, which means the texture you dial in at the mixer shows up again in the oven. It’s a simple way to protect color, lift, and bite while you raise throughput.

Match The Mixer To The Job

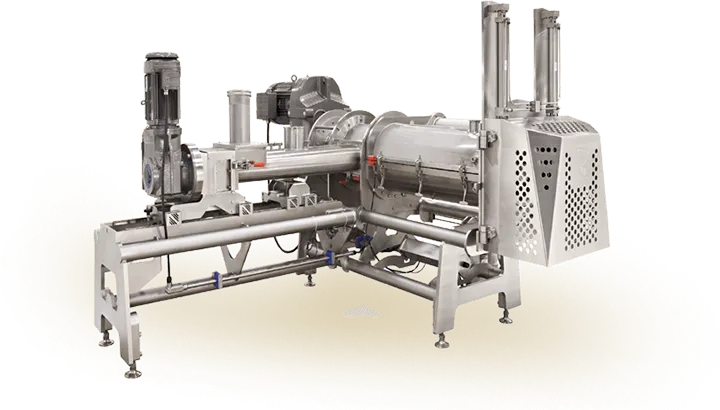

Continuous mixing isn’t one size fits all, so we offer different Exact models for different products. Our EX Continuous Mixer is a proven choice for low-absorption, wheat-based doughs – think crackers, pretzels, bagels, pizza, and sweet goods – where you want gentle development without excess heat.

If you run ultra-high-absorption bread or bun doughs, the HDX High Development Mixer uses a two-stage design to mix and then knead to the right level at low temperatures, ideal for buns, rolls, tortillas, and English muffins.

Less Waste, Easier Days

Consistency is its own kind of speed. When dough looks and feels the same every minute, operators spend less time chasing adjustments at the sheeter, fewer pieces fall out of spec, and the oven stays in its sweet spot. Continuous mixing also simplifies sanitation and changeovers because ingredients are metered and enclosed; you’re not wrestling with repeated full-tub transfers.

Putting It To Work

We’ll help you size and configure the right Exact Mixing system for your line, from ingredient delivery to the handoff at forming. If your goal is faster cracker and pretzel output with the same signature texture, an EX Mixer with Hydrobond is a strong, low-risk upgrade. If your roadmap includes buns or tortillas, HDX brings the development your doughs require at the temperatures they prefer.

The experts with Reading Bakery Systems can show you how RBS continuous mixing can speed up production without affecting product quality. Get in touch by using our online contact form or calling 610-693-5816.