The best commercial bakery mixing equipment in Columbia – products from Reading Bakery Systems – perform in the most challenging environments. Anyone who’s worked a humid summer shift knows the feeling – yesterday’s dough ran like a dream, today it feels tacky, sheets too thin, and the oven team is scrambling to rescue color. With the right mixing technology and a few smart process choices, we can keep hydration steady and give your downstream equipment the consistency it craves.

The best commercial bakery mixing equipment in Columbia – products from Reading Bakery Systems – perform in the most challenging environments. Anyone who’s worked a humid summer shift knows the feeling – yesterday’s dough ran like a dream, today it feels tacky, sheets too thin, and the oven team is scrambling to rescue color. With the right mixing technology and a few smart process choices, we can keep hydration steady and give your downstream equipment the consistency it craves.

Why Humidity Trips Up Dough

When the air is wet, flour and dry blends absorb more ambient moisture before they ever reach the mixer. That sneaks extra water into the process and pushes dough toward sticky, over-developed behavior. Humidity also changes heat transfer. Warmer, wetter air raises dough temperature faster, which nudges gluten development and can make a once-reliable formula feel unpredictable. If the mix room is chasing those swings, your sheeter, laminator, and oven end up chasing them, too.

Stabilize Hydration At The Source

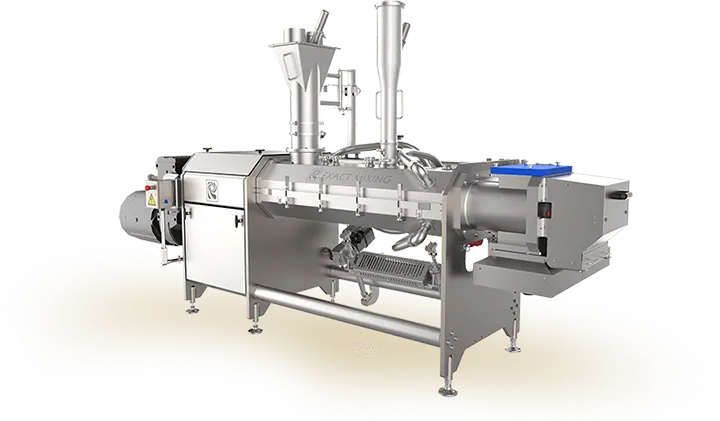

We designed our Exact Mixing systems to take the guesswork out of wet-out. Hydrobond™ Technology instantly combines dry ingredients with a pressurized, atomized stream of liquid before the dough enters the mixing chamber. Because powders meet micro-droplets instead of a big slug of water, hydration is fast and uniform – even when the weather isn’t. That early, even wet-out reduces the “dry pockets” and over-worked streaks that humid days tend to amplify, so you start every run closer to the texture you want.

Control Temperature, Control Texture

Humidity and heat like to travel together, which is why dough temperature control is your best friend. Our Exact mixers are built to manage development at a steady state, so mechanical energy and frictional heat don’t spike just because the forecast did. The EX Continuous Mixer keeps wheat-based snack doughs gentle and predictable for crackers, pretzels, and baked crisps.

When you need more strength in high-absorption formulas – think buns, rolls, tortillas, or English muffins – our HDX High Development Mixer uses a two-stage process to mix and then knead at lower dough temperatures. Lower heat during development means fewer sticky surprises when humidity climbs.

Reduce Exposure, Reduce Variability

Every time dough stops and waits, it exchanges heat and moisture with the room. That’s why a steady, continuous process often feels calmer on muggy days. With continuous mixing, ingredients are enclosed and metered, dough development happens in a controlled zone, and finished dough goes straight to forming. You’re not parking tubs under humid air or restarting downstream equipment after the bowl is scraped. The result is a smaller weather “footprint” on your product and fewer last-minute fixes at the sheeter.

Choose The Right Mixer For Your Portfolio

Humidity headaches don’t show up the same way in every formula, so we match the tool to the job. If you run a wide variety of cookies, snacks, batters, and pastes, our MX Continuous Mixer is a flexible workhorse that maintains flow while keeping development consistent across SKUs.

For low-moisture, powder-heavy products like fabricated chips, our FX model uses high-speed mixing to lift powder into atomized liquid for clean hydration and tight texture control. Pair any of these with Hydrobond and you’ll feel the benefit most on the stickiest days of the year.

You can call Reading Bakery Systems at +1 610-693-5816 or use our online form to learn more about our commercial bakery mixing equipment in Columbia.