At Reading Bakery Systems, we build commercial bakery mixing equipment in Japan with repeatability in mind, because consistent dough is what keeps production efficient and top-quality. The goal is simple: you want the same recipe to behave the same way, whether it’s running on Line One, Line Four, Plant A, or Plant C. Here’s a look at why you should consider contacting us.

At Reading Bakery Systems, we build commercial bakery mixing equipment in Japan with repeatability in mind, because consistent dough is what keeps production efficient and top-quality. The goal is simple: you want the same recipe to behave the same way, whether it’s running on Line One, Line Four, Plant A, or Plant C. Here’s a look at why you should consider contacting us.

Consistency Starts With How Ingredients Get Delivered

Most bakeries don’t struggle because they lack good recipes. They struggle because the recipe doesn’t get delivered the same way every time. When ingredients are staged differently, weighed slightly off, or added in a different order during a busy shift, the dough can drift. That drift gets worse when you multiply it across multiple sites.

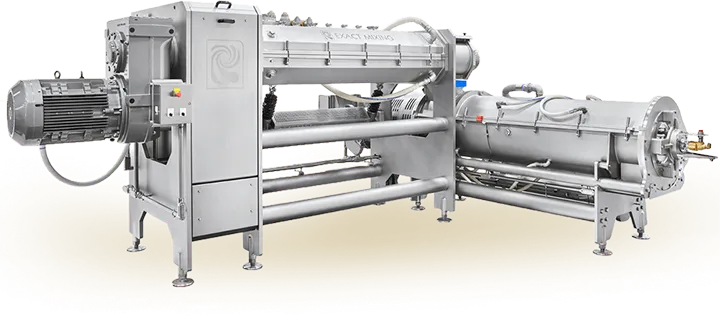

Our continuous mixing systems are designed around accurate ingredient delivery directly into the mixer, so you’re not relying on a chain of separate handoffs to stay on target. With Exact Mixing continuous mixer systems, feeding and the control system work together to monitor and initiate metering and mixing procedures. The system helps keep your inputs steady so your output stays steadier. That kind of repeatability becomes even more valuable when you’re trying to standardize results across plants that may have different staffing patterns or shift routines.

A Steady Process Helps Multiple Lines Run More Alike

Batch mixing can create a natural stop-and-start rhythm, and that rhythm can make every line feel like it has its own personality. One line runs great early, another line runs better after the second batch, and suddenly you’re chasing timing instead of building consistency.

Continuous mixing is built to support a smoother flow into the rest of the process. When dough arrives in a steadier way, the rest of the line can run more predictably. That predictability helps operators make fewer on-the-fly adjustments. Over time, that reduces the gap between lines, because the mixing stage stops introducing as much variation.

Matching the Mixer to the Product Keeps Results Predictable

Another key to multi-site consistency is choosing mixing equipment that fits what you make. A single approach does not always work across cookies, crackers, bread, buns, batters, or fillings. When a mixer is forced to operate outside its comfort zone, your team ends up compensating, and compensation is where variation sneaks in.

We offer a full line of Exact Mixing continuous mixer models, so the mixing style can match the product. The following is a brief look at each.

- The MX Continuous Mixer is known for versatility across products like cookies, snacks, batters, icings, and pastes, and it can also serve as a first-stage mixer in multi-stage processes.

- The EX Continuous Mixer is built for wheat-based products where gentle kneading supports consistent development.

- For higher development needs in ultra-high absorption doughs like breads and buns, the HDX Continuous Mixer is designed to deliver highly developed dough while keeping temperature control in view.

Significant Advantages

The benefit of having these options is practical. When each plant uses equipment that truly fits the product set, the process becomes easier to standardize across your organization.

We also support complete mixing solutions that can include the mixer, blender, materials handling, ingredients metering, and the control system, along with testing and installation supervision. That full system mindset helps you avoid the patchwork setups that behave differently from one site to the next.

See why we offer the best commercial bakery mixing equipment in Japan by using our online form or calling Reading Bakery Systems at +1 610-693-5816.