Choosing between batch and continuous mixing isn’t a philosophical debate – it’s a practical call about the products you make, the pace you need, and how your team works best. Batch mixing gives you a familiar, stop-and-start rhythm with clear checkpoints. Continuous mixing replaces that rhythm with a steady stream of developed dough that feeds the line without pauses. The question is which approach lines up with your formulas, your schedule, and your growth plans. We’ll walk you through a simple way to decide, and where the Exact Mixing portfolio from Reading Bakery Systems – the gold standard when it comes to commercial bakery mixing equipment in the UAE – can help.

Choosing between batch and continuous mixing isn’t a philosophical debate – it’s a practical call about the products you make, the pace you need, and how your team works best. Batch mixing gives you a familiar, stop-and-start rhythm with clear checkpoints. Continuous mixing replaces that rhythm with a steady stream of developed dough that feeds the line without pauses. The question is which approach lines up with your formulas, your schedule, and your growth plans. We’ll walk you through a simple way to decide, and where the Exact Mixing portfolio from Reading Bakery Systems – the gold standard when it comes to commercial bakery mixing equipment in the UAE – can help.

Start With Your Products

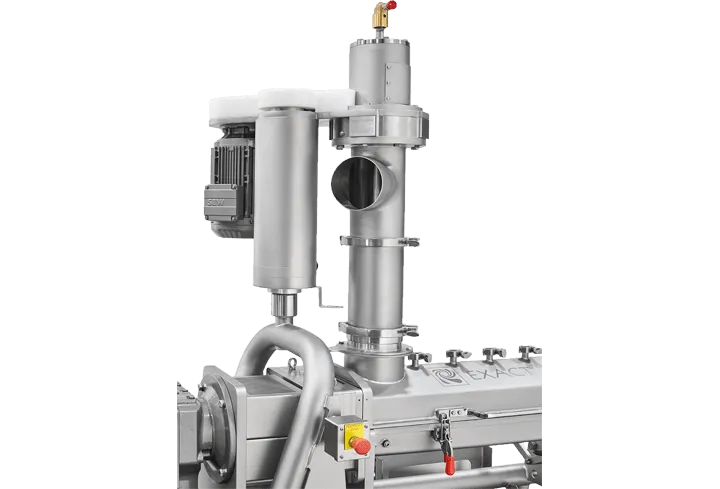

Begin with your menu. If you live in crackers, pretzels, and other wheat-based snacks that run for long stretches, continuous mixing often shines because it keeps dough characteristics stable from the first minute to the last. Our Exact EX Continuous Mixer was built for that world, delivering gentle, consistent development at a constant output. If you’re running a wide variety of short cookie or snack batches through the day, a well-run batch process may still make sense – or you can bridge the gap with our Exact MX, which handles diverse doughs and pastes while maintaining steady flow to forming.

Look At Throughput And Rhythm

Think about how your line actually moves. Batch mixing naturally creates peaks and valleys as bowls fill and empty. That can work if downstream equipment is used to that cadence. Continuous mixing smooths those peaks into one predictable pace, which helps sheeters, laminators, and ovens settle into stable settings. Need high development in very wet doughs for buns, rolls, or tortillas? Our Exact HDX system uses a two-stage approach to build strength at low temperatures, so you can maintain output without overheating the mix room – or the dough.

Quality And Consistency

Speed isn’t the only goal; you need the same bite, color, and cell structure every run. Batch mixing can produce excellent quality, but the first and last bowls of a shift sometimes feel different. Continuous mixing holds ratios, dough temperature, and mechanical energy steady, which narrows the target for the oven and packaging. When you add our Hydrobond Technology – instant, uniform hydration upstream of the mixing chamber – you reduce “hot spots” of dry or over-worked material and protect the texture your customers expect. That’s how you run faster without changing the way the product eats.

People, Space, And Sanitation

Your plant layout and team count matter. Batch mixing can demand more manual handling, staging, and tub traffic. Continuous mixing centralizes metering and development, reducing lifts and transfers while keeping ingredient streams enclosed. That’s good for allergen control and for a cleaner mix room.

Our systems are designed for quick verification and straightforward washdowns, so operators can prove readiness and get back to making good dough. If floorspace is tight, we’ll help you design an ingredient delivery and mixer footprint that fits without crowding the line.

Try It Before You Commit

The best decision is the one you’ve proven with your own formulas. We invite you to run side-by-side trials at our Science & Innovation Center, where we can benchmark your current batch process against a continuous setup, fine-tune hydration with Hydrobond, and capture the data you need to make a confident call. You’ll see how dough behaves on the mixer, how it sheets, and what the bake looks like on a real line.

Find out more about our commercial bakery mixing equipment in the UAE by calling Reading Bakery Systems at +1 610-693-5816 or contacting us online.