Great snacks are built on consistency – dough that behaves the same at 6 a.m. as it does at 6 p.m., sheet widths that stay true, and bakes that match yesterday’s gold standard. Efficiency follows that steadiness. When the line doesn’t yo-yo, your team stops scrambling and starts producing. At Reading Bakery Systems, we design equipment and systems that ensure consistency and efficiency in snack manufacturing to help you lock in a predictable rhythm so output rises without asking people to sprint.

Great snacks are built on consistency – dough that behaves the same at 6 a.m. as it does at 6 p.m., sheet widths that stay true, and bakes that match yesterday’s gold standard. Efficiency follows that steadiness. When the line doesn’t yo-yo, your team stops scrambling and starts producing. At Reading Bakery Systems, we design equipment and systems that ensure consistency and efficiency in snack manufacturing to help you lock in a predictable rhythm so output rises without asking people to sprint.

Small Variations, Big Consequences

A few seconds added to mixing, an extra turn on a gauge roll, or a slightly uneven water add can ripple into scrap, rework, and overtime. The trick is to smooth out those little bumps before they become big ones. We focus on giving your operators simple controls, clear visual cues, and equipment that reacts the same way every time. When settings stick and product responds, the whole plant moves faster with less effort.

Hydration First: How We Keep The Dough Cooperative

Hydration is the moment that sets the tone for everything downstream. Our Hydrobond Technology steps in precisely there – not as a flashy add-on, but as a quiet stabilizer. By helping water meet dry ingredients evenly right up front, Hydrobond sets you up with dough that’s ready to cooperate. You’ll feel less tug-of-war at the sheeter, see cleaner cuts at the rotary molder, and notice that startup settles sooner. It’s the kind of behind-the-scenes assist that keeps consistency from slipping away on busy days.

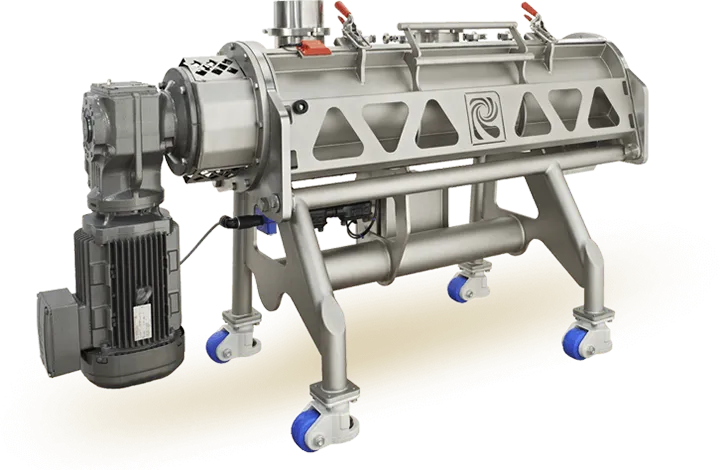

Continuous Mixing As The Plant’s Metronome

Batch changes can make a line feel stop-start. Our Exact Mixing continuous equipment turns that on/off cadence into a steady tempo. Ingredients are metered, mixed, and delivered in a controlled flow, so forming and baking see the same dough personality hour after hour. We tailor the system to your formulas and targets, then make it easy to call up recipes and keep them true. The payoff isn’t just capacity; it’s the calm that lets operators focus on quality rather than constant correction.

Better Hand-Offs Mean Faster Bakes

When dough shows up consistent, ovens can do their best work. Temperatures stabilize quickly, color evens out, and moisture finishes on point. That reduces the nips and tucks at the end of the bake that slow throughput. With steadier inputs from Hydrobond-assisted hydration and continuous mixing, you can hold tighter bands without babysitting every zone. The result is less scrap and more first-pass product that looks and tastes exactly as intended.

Cleanliness, Changeovers, And The Human Side Of Efficiency

Efficiency isn’t just speed; it’s how easy the work feels. When hydration is even and dough development is repeatable, you get less dust, fewer sticky surprises, and faster wipe-downs. That makes changeovers smoother and training friendlier. We build our systems so operators can see what “good” looks like at a glance and reset with confidence. Fewer second guesses mean less idle time and happier shifts.

Turning Information Into Action

Data should be helpful, not heavy. We provide straightforward trends, alarms, and recipe management so teams can spot drift early and correct it fast. Think of it as a dashboard that backs up what your crew already sees and feels on the line. When information confirms instincts, decisions happen quickly, and the process stays on track.

Learn more about how Reading Bakery Systems equipment promotes consistency and efficiency in snack manufacturing by contacting us online or calling 610-693-5816.