At Reading Bakery Systems, when we sell continuous mixing equipment for industrial bakeries in Germany, we don’t just disappear. We make sure your team can use that equipment easily and efficiently. Here are a few tips to help your workers do just that.

At Reading Bakery Systems, when we sell continuous mixing equipment for industrial bakeries in Germany, we don’t just disappear. We make sure your team can use that equipment easily and efficiently. Here are a few tips to help your workers do just that.

Learn The Flow, Not Just The Buttons

Controls matter, but understanding the path ingredients take matters more. You’ll see dry ingredients metered consistently, liquids added at controlled rates, and dough forming continuously before heading to sheeting or forming.

When you know that sequence by heart, the HMI becomes a helpful companion instead of a mystery panel. We keep our interfaces clear – plain-language recipe names, sensible ranges, and guided start-up prompts – so you can focus on cause and effect: if the feed is steady, the dough is steady, and the line stays steady.

The First 10 Minutes Matter Most

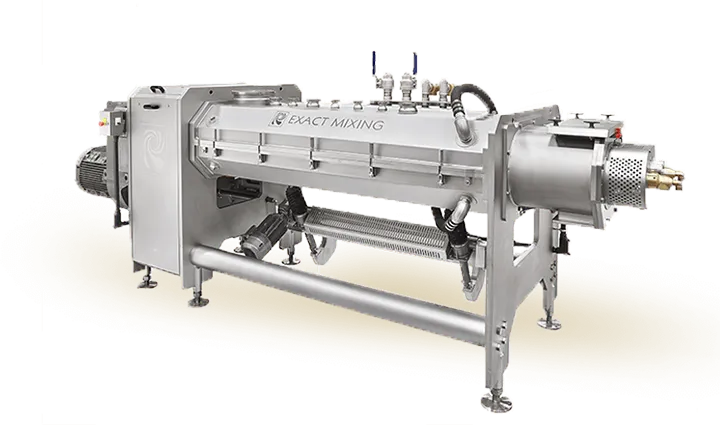

Early minutes set the tone for the entire shift. Watch dough temperature, appearance, and feel as the system reaches its target rate. If the dough looks tight, you may be seeing the system come up to speed, not a problem to fix. Give it a moment while your readings stabilize, then make small, deliberate adjustments. Our Exact Mixing equipment stores proven recipes and lets you lock in setpoints, so you’re not chasing a moving target.

Training That Sticks And Travels

A good first run is one everyone can repeat on the second. That’s why we pair our equipment with straightforward SOPs and hands-on training at our Innovation Center. You’ll practice start-ups, learn how to pause and resume without drama, and see how minor adjustments show up in real product. Because the process is steady and the controls are intuitive, cross-training becomes easier. New team members build confidence quickly, and experienced operators spend more time coaching than firefighting.

Sanitation And Changeovers Without The Headache

Efficiency isn’t just run speed – it’s how quickly you can change course. With fewer bowls to clean and a tidier mixing area, changeovers feel shorter and less stressful. Our designs prioritize access and cleanability, so wipe-downs are straightforward and restarts are smooth. The payoff is time you actually feel: you’ll get back to producing faster, with fewer trial pieces to dial in.

How We Set You Up To Succeed

We don’t drop off a mixer and wish you luck. We help you choose the Exact Mixing configuration that fits your formulas and rate, create recipe libraries that reflect how you really run, and map start-up routines your crew can follow without a playbook. If you’re pairing mixing with our ovens or pretzel systems, we’ll align targets so the entire line hums at the same pace. The goal is a first day that feels familiar by lunchtime and second nature by week’s end.

Troubleshooting Without The Panic

If something drifts, breathe. Look at the trends, confirm you’re on the right recipe, and make one measured adjustment. Continuous mixing gives you the gift of stability; small, timely moves go a long way. We build in gentle alarms and visual cues so you’ll see drift before the product tells the story. Most “issues” on day one are simply the system and team finding a shared rhythm.

See why so many companies turn to Reading Bakery Systems for continuous mixing equipment for industrial bakeries in Germany. You can use our online form or call +1 610-693-5816.