If you run a commercial bakery today, you already know staffing pressure is not a passing issue. Open roles sit longer, training takes more time, and one absence can ripple through the whole shift. When that happens, mixing often becomes the stress point. If the mixer falls behind, the rest of the line either waits or rushes, and nobody enjoys either option. Continuous mixing equipment for industrial bakeries in the UAE from Reading Bakery Systems can help you build a calmer, more repeatable workflow.

If you run a commercial bakery today, you already know staffing pressure is not a passing issue. Open roles sit longer, training takes more time, and one absence can ripple through the whole shift. When that happens, mixing often becomes the stress point. If the mixer falls behind, the rest of the line either waits or rushes, and nobody enjoys either option. Continuous mixing equipment for industrial bakeries in the UAE from Reading Bakery Systems can help you build a calmer, more repeatable workflow.

Fewer Hands-On Tasks Means Less Daily Scramble

Batch mixing tends to create a steady stream of small jobs that pull people in different directions. Someone stages ingredients, another worker watches timing, and another handles hand-adds. Someone else resets for the next batch. When staffing is thin, those tasks stack up, and the shift can feel like it is always behind.

Continuous mixing changes the rhythm, since ingredients are metered into the process on an ongoing basis. That can reduce the number of times your team has to stop production to load, dump, and restart. When the process runs in a steadier flow, it’s easier to assign clear roles and keep people focused on quality instead of constantly catching up.

Repeatable Results Help New Operators Succeed Faster

Training is tough when the process depends on feel. A seasoned operator might know how to spot a dough change and correct it quickly. However, newer team members often need time to develop that confidence. When turnover is high, that learning curve can become a real constraint.

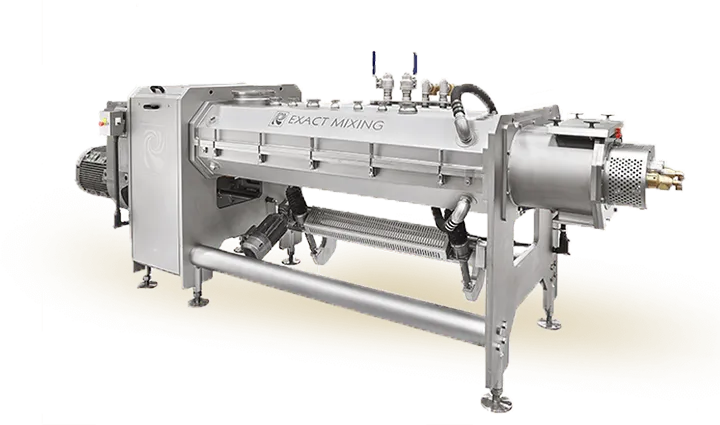

Our Exact Mixing continuous mixer systems are built to support repeatability through controlled ingredient delivery and a consistent mixing approach. That kind of consistency helps new operators learn what “good” looks like sooner, because the process is more predictable from run to run. It also reduces the pressure on your most experienced people, since they are not constantly pulled away to fix small problems at the mixer.

A Steadier Dough Supply Reduces Line Stress

Staffing pressure isn’t only about headcount. It’s also about how stressful the shift feels. When the line keeps waiting for the next batch, everyone feels it. Makeup crews speed up, then slow down. Supervisors move people around. Quality checks get rushed. Even if the team pushes through, that kind of day burns people out.

Continuous mixing can help by delivering a steady stream of mixed product to the discharge instead of intermittent dumps. When dough supply is steadier, downstream equipment can run more consistently. That stability makes scheduling easier, makes changeovers feel less chaotic, and helps the whole line run with fewer urgent decisions.

The Right Mixer Fit Can Simplify Your Product Mix

We offer multiple continuous mixer models so you can match the mixing approach to your products and your goals.

The MX Continuous Mixer is known for versatility across product types, while the EX model supports wheat-based products where consistent dough development is critical.

The LDX can support staged mixing for processes that benefit from a crème up stage and a final mix stage.

The FX and HDX options help address specific development needs for certain dough styles.

When the equipment fits the product, the process gets simpler for the operator, and that’s exactly what you want when staffing is tight. Find out more about continuous mixing equipment for industrial bakeries in the UAE from Reading Bakery Systems by using our online form or calling +1 610-693-5816.