With continuous mixing for industrial bakeries in Turkey, it’s easy to assume return on investment is far down the road because the system feels like a big shift from batch mixing. In reality, many bakeries see the return show up sooner than expected because the savings don’t come from one dramatic change. They come from several practical improvements that stack together every shift. That’s especially true when bakeries choose equipment from Reading Bakery Systems.

With continuous mixing for industrial bakeries in Turkey, it’s easy to assume return on investment is far down the road because the system feels like a big shift from batch mixing. In reality, many bakeries see the return show up sooner than expected because the savings don’t come from one dramatic change. They come from several practical improvements that stack together every shift. That’s especially true when bakeries choose equipment from Reading Bakery Systems.

The Fastest ROI Usually Comes From Stopping Waste

Most bakeries don’t lose money because the recipe is wrong. They lose money because the process leaks. Dough gets over mixed, under mixed or adjusted too late. Some runs turn into rework while others get downgraded. Even if the scrap numbers look small, they add up when production is high volume.

Continuous mixing helps reduce that process drift because ingredients are metered and mixed continuously instead of being handled in batches that can vary from one cycle to the next. When output is more consistent, you’ll usually see fewer off-spec moments and fewer corrections that require extra time and extra ingredients. Over time, that reduction in waste can become one of the strongest drivers of faster payback.

Higher Throughput Can Arrive Without Adding Chaos

ROI gets faster when you can increase output without increasing stress. Batch mixing tends to create natural pauses. You mix, dump, reset, and repeat. Those gaps can leave downstream equipment waiting, which means you’re paying for labor and machine time that isn’t fully producing.

We design our continuous mixing systems to deliver a steady stream of mixed product at the discharge, which supports a more continuous production flow. When the line isn’t waiting on the next dump, the rest of the process can run more predictably. That steadier rhythm often lets bakeries push higher throughput without the same level of schedule volatility. The result isn’t just more product. It’s more product with less disruption, which is exactly the kind of improvement that supports a quicker return.

Labor Savings Are Often Real Even If You Don’t Cut Headcount

When people hear labor savings, they sometimes think it means eliminating roles. That’s not always the story. In many bakeries, the bigger win is reducing overtime, reducing constant coverage problems, and making it easier to run a full shift with the staffing you can actually hire.

Continuous mixing can reduce repetitive handling tasks that come with batch cycles, and it can support a more predictable operator routine. Our systems support controlled ingredient delivery and repeatable mixing action, so the operator isn’t stuck making constant on-the-fly adjustments. That can improve training and reduce the pressure placed on a few highly experienced people. When staffing is tight, those changes can quickly show up as fewer schedule disruptions and fewer costly slowdowns.

Systems Support Can Shorten the Path to Payback

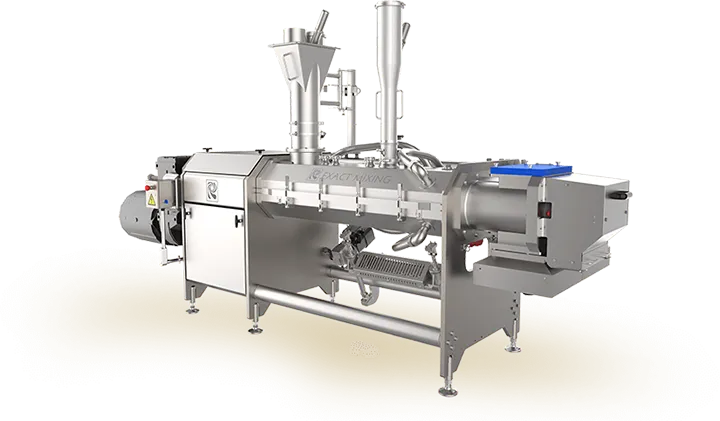

Faster ROI is also about implementation. A great mixer doesn’t help if the rest of the system is held together by workarounds. We support complete mixing solutions that can include ingredient metering, materials handling, controls, and testing support. We also offer Hydrobond technology for rapid hydration in continuous mixing applications, which can support consistent dough while helping the process run efficiently. When the system’s built to work together, you can reach stable production sooner, and that can shorten the payback timeline.

For more information on continuous mixing for industrial bakeries in Turkey, use our online contact form or call +1 610-693-5816.