Cracker production line equipment in Guatemala faces tougher challenges than in other parts of the world due to altitude. Change the air pressure, and suddenly the bubbles, snap, and color degrade. That’s life in Guatemala’s high-elevation cities – beautiful views, trickier baking physics. The good news is you don’t have to accept “close enough.” With the right oven configuration, airflow strategy, and dough management, you can make altitude feel like just another spec. At Reading Bakery Systems, we help you build that control into the line so your crackers stay crisp, flat, and consistently golden.

Cracker production line equipment in Guatemala faces tougher challenges than in other parts of the world due to altitude. Change the air pressure, and suddenly the bubbles, snap, and color degrade. That’s life in Guatemala’s high-elevation cities – beautiful views, trickier baking physics. The good news is you don’t have to accept “close enough.” With the right oven configuration, airflow strategy, and dough management, you can make altitude feel like just another spec. At Reading Bakery Systems, we help you build that control into the line so your crackers stay crisp, flat, and consistently golden.

What Altitude Changes Inside The Oven

Lower air pressure means water boils at a lower temperature and evaporates faster. For thin products like crackers, this can create dry skins early in the bake, trapping moisture inside and encouraging warping or exaggerated blistering. Gas cells also expand more readily, which can stretch laminations or docking patterns beyond their sweet spot.

Our Thomas L. Green PRISM OVEN and Reading Pretzel SPECTRUM OVEN® platforms give you independent control of top and bottom heat and zone-by-zone airflow, so you can slow the early skin-forming effect while still moving moisture efficiently through the core.

Dialing Zones For Moisture First, Finish Second

At elevation, we like to stage the bake curve more deliberately. Early zones work as moisture movers; later zones focus on color and texture. Using our Emithermic and Convection zones in the front third of the PRISM OVEN, we’ll push high, directed air with tuned exhaust/make-up to thin the boundary layer and pull water out without scorching.

In the back half, radiant-forward energy brings the Maillard finish and the delicate snap you expect. If you’re replacing legacy direct gas fired sections, our Emithermic XE technology blends radiant panels with forced convection to replicate the color development you remember – minus open flame – and to keep results steady from cool mornings to rainy afternoons.

Airflow, Exhaust, And Humidity Control That Earn Their Keep

Guatemala’s highlands can swing between dry, sunny days and damp, misty nights. That variability shows up fast in open product areas. We configure SPECTRUM and PRISM zones so you can adjust air velocity and humidity independently on the fly.

A small increase in make-up air when ambient humidity rises can keep your evaporative rate on target; a slight trim on top air speeds will calm blister formation when pressure and dough gassing want to run away. Because our designs separate top and bottom plenums, you steer lift and color precisely across the belt – even on wide ovens.

Dough And Forming Tweaks That Pay Off

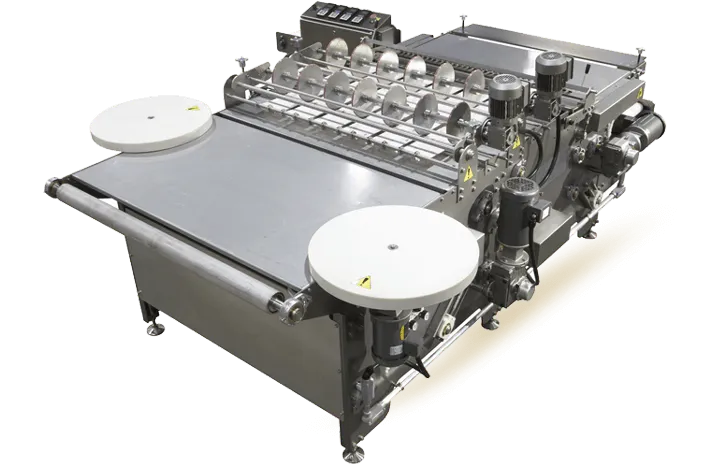

Altitude amplifies whatever your dough is already doing. Consistent hydration and temperature make the oven’s job much easier. Our Exact Mixing continuous systems meter flour, water, and minors with tight accuracy, then use Hydrobond Technology to combine dry and liquid phases instantly for uniform hydration. You’ll feed the sheeter a calmer dough, which helps laminations stay orderly and docking work as intended.

Make High Elevations Work For You

Baking crackers at elevation isn’t about fighting the mountain – it’s about respecting the physics and giving yourself better levers. Cracker production line equipment in Guatemala will turn the altitude into an advantage, not a variable – so every box shipped tastes exactly like the brand you’ve promised. Put us to the test by using our online contact form or calling Reading Bakery Systems at +1 610-693-5816.