When it comes to enhancing dough hydration levels for better results, nothing beats Hydrobond Technology from Reading Bakery Systems. When dough doesn’t get enough water at the start, proteins and starches never quite meet the way they should. That shows up later as tougher handling, poor forming, and bakes that just look “off.” The good news is that under-hydration is fixable, and once you see its fingerprints on texture and shape, you can make simple changes that pay off fast.

When it comes to enhancing dough hydration levels for better results, nothing beats Hydrobond Technology from Reading Bakery Systems. When dough doesn’t get enough water at the start, proteins and starches never quite meet the way they should. That shows up later as tougher handling, poor forming, and bakes that just look “off.” The good news is that under-hydration is fixable, and once you see its fingerprints on texture and shape, you can make simple changes that pay off fast.

Texture Troubles You Can Feel

Under-hydrated dough feels tight and resistant. It fights the sheeter, snaps back after you roll it, and asks for extra energy in mixing and forming. In the oven, that tension becomes toughness. Crackers crunch in a hard, almost glassy way rather than giving a clean, delicate snap. Pretzels lose that smooth, satiny bite and lean rubbery. Cookies hold too much height, turning cakey instead of tender. All of that comes from particles that never fully absorbed water, so the dough can’t relax and develop a friendly, cohesive structure.

Spread, Lift, And Shrink

Shape tells the hydration story at a glance. Under-hydrated cracker dough tends to shrink at the edges, causing uneven geometry and a “pulled” look after baking. Sheet lines can show wrinkling or edge tears because the dough resists stretch. For cookies, poor hydration means less spread and more doming, so you lose that target diameter and uniform thickness. Even baked chips will show more blister variation and cup unpredictably. When the dough hasn’t “had enough to drink,” it can’t flow evenly through forming, and the oven simply locks in those imbalances.

How To Spot It During A Busy Shift

You don’t need a lab to catch under-hydration. Watch for dough that breaks rather than stretches, sheets that keep creeping narrower, and cutters that need extra pressure to release cleanly. Look at finished pieces: are the edges scalloping, are surfaces rough instead of smooth, and are diameters stubbornly small? If the team starts compensating with more mixing, higher forming force, or constant tweaks at the oven, you’re likely treating symptoms of water that never got where it needed to go.

How We Help: Hydrobond’s Gentle Head Start

At Reading Bakery Systems, we tackle the root cause with our Hydrobond Technology. Instead of dumping water and hoping it finds every dry particle, we help water meet flour efficiently and consistently upstream. Think of it as giving the dough a proper drink before it ever reaches the mixer. Because hydration begins sooner and more evenly, the mass relaxes faster, handles more willingly, and forms predictably. You’ll feel the difference in the bowl and see it on the belt: smoother surfaces, cleaner cuts, steadier widths, and finished pieces that hold the shape you intended.

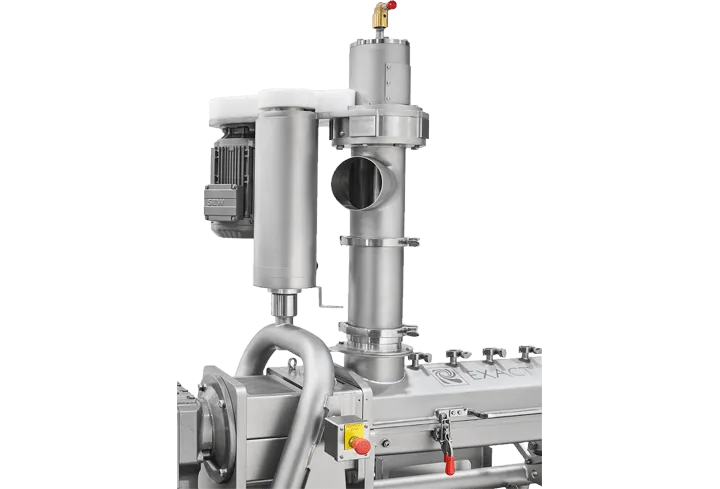

Pairing With Continuous Mixing For Everyday Stability

Hydration is only half the story; the other half is how you keep it steady. Our Exact Mixing continuous systems meter dry and liquid ingredients at controlled rates and mix them into a uniform stream of dough. When Hydrobond kick-starts water absorption and continuous mixing keeps the flow consistent, your team spends less time “coaxing” dough and more time running on spec. That combination supports better texture – snaps are cleaner, bites are friendlier – and shape targets become easier to hit across long runs and quick changeovers.

Let Us Help Your Hydration Levels Stay Perfect

When hydration is right from the start, forming is smoother, bakes look better, and the finished bite matches the promise on the package. That’s the everyday win we love helping you achieve. Find out more about enhancing dough hydration levels for better results by using our online form or calling Reading Bakery Systems at 610-693-5816.