Reading Bakery Systems is the leading industry supplier of efficient, high volume snack systems, including economical fried potato ring manufacturing equipment. We design, engineer and manufacture the world’s most advanced commercial baking equipment to help customers discover more efficient ways of making their products.

Headquartered in Robesonia, Pennsylvania, Reading Bakery Systems (RBS) understands the dynamic nature of the global baked snack food industry. We offer high-quality solutions to customers in the global food and snack industries, providing reliable and efficient systems for the production of cookies, crackers, biscuits, pretzels, baked potato chips, bread snacks, baked crisps, pet treats and more.

Turnkey Production System

Our extrusion-based Fried Potato Ring System is ideal for the flexible, efficient, high volume production of extruded fried snacks, such as the popular fried potato ring product, and is capable of producing from 200-1000 kg/hr of finished product.

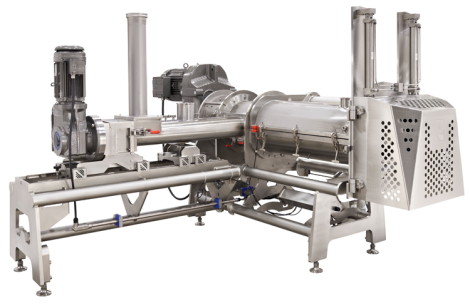

Continuous Mixing Equipment

Consider our continuous mixing technology when you are interested in producing a more consistent dough and finished product.

The Exact Mixing FX Continuous Mixer is designed to distribute small amounts of moisture evenly into large amounts of powder. A high-speed mixing shaft lifts powdered ingredients into and through atomized liquids sprayed into the mixing chamber. This efficient mixing process is well suited for hydroscopic powders such as potato flakes used to make fabricated potato chips or any other low moisture mixtures.

Extrusion Equipment

The Reading Pretzel Fried Snack Extruder creates fried snacks, including potato rings, potato sticks and ethnic noodles. The extruded product is delivered to the fryer* by a belted conveyor or by incorporating an optional oil “free float” conveying section. The Extruder with pre-feed rollers manages dough flow for optimum consistency from the time it enters the infeed hopper through being cut off at the die face by the high-speed bandcutter. (*Fryer not supplied by RBS)

RBS Science & Innovation Center

The innovative spirit of Reading Bakery Systems is on full display at the 30,000 square foot RBS Science & Innovation Center in Sinking Spring, Pennsylvania, where we demonstrate solutions for our customers and partner with them to look for new product and equipment solutions.

This Center is a fully equipped, licensed food processing research and development facility where customers can work with our team to test new machinery and processing techniques; research innovations in mixing, forming, baking and drying that can increase profitability; validate new ingredients and test ingredient changes; and produce market samples for testing.

Find out more about fried potato ring manufacturing equipment and other innovative bakery equipment from Reading Bakery Systems. Call us at (01) 610-693-5816 or click here to contact us online.