If you’re wondering how continuous mixers improve dough consistency, they do so by delivering a steady stream of mixed product, so your process increases efficiency and stays more predictable. Continuous mixers from Reading Bakery Systems are built to make consistency easier to achieve and easier to repeat, rather than producing dough in separate batches that can vary from cycle to cycle.

If you’re wondering how continuous mixers improve dough consistency, they do so by delivering a steady stream of mixed product, so your process increases efficiency and stays more predictable. Continuous mixers from Reading Bakery Systems are built to make consistency easier to achieve and easier to repeat, rather than producing dough in separate batches that can vary from cycle to cycle.

A Steady Ingredient Flow Helps Create a Steady Dough

Inconsistency typically starts before the mixer even does its job. When ingredients arrive in uneven amounts, or they’re added at slightly different times, the dough can change even if the recipe never does. Batch mixing tends to magnify that issue because every batch is a fresh reset. If something is a little off, the whole batch carries that difference forward.

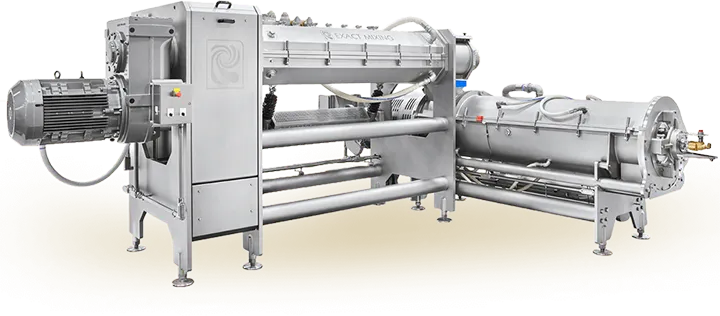

Our Exact Mixing continuous mixer systems meter ingredients into the mixing process on an ongoing basis. That steady delivery supports a steadier outcome, because the mixer is working with a more consistent stream of inputs. The practical benefit is simple. When the process stops jumping from batch to batch, your dough has fewer chances to swing.

Better Hydration Can Make Dough More Predictable

Dough consistency isn’t just about the mixer running. It’s about how evenly ingredients come together, especially liquids and dry ingredients. If hydration is uneven, you can end up with dough that behaves differently from one run to the next, even when you think you did everything the same.

That’s one reason we offer Hydrobond technology for rapid hydration in continuous mixing applications. It helps bring ingredients together quickly and evenly, so the mix does not rely on extra time or extra correction. You do not need the process to be complicated. You need it to be repeatable, and hydration is a big part of repeatability.

Choosing the Right Mixer Model Helps Protect Consistency

Not every product needs the same mixing approach. If the mixer is not a good match for what you’re making, operators end up compensating, and compensation is where variation sneaks in. Consistency gets easier when the equipment fits the product instead of fighting it.

We offer multiple continuous mixer models so you can align the mixer with your dough and your production goals. When the mixer matches the application, the process becomes more predictable, and that predictability shows up as better consistency.

A Complete System Approach Helps You Hold the Gains

Even a great mixer can only do so much if the surrounding process is patchwork. If ingredient delivery is inconsistent or the system depends on manual workarounds, consistency becomes harder to sustain, especially when staffing changes or production ramps up.

That’s why we support complete mixing solutions that can include ingredient metering, materials handling, controls, and testing support. When the system works together, the mixer isn’t carrying the full burden of consistency on its own. Your whole process is built to repeat results more reliably.

We’re Ready to Tell You More

How do continuous mixers improve dough consistency? Reading Bakery Systems achieves this by smoothing out the biggest sources of variation: uneven ingredient delivery, stop-and-start batch cycles, and hydration differences that creep in over time. When the process is steadier, the dough is steadier, and the rest of the line can run with fewer surprises. Speak with one of our experts by contacting us online or calling 610-693-5816 for more information.