When a bakery gets big, quality control gets harder, not easier. You might have multiple lines, shifts, and plants, all trying to hit the same color, texture, and moisture targets every single day. How do large bakeries maintain consistent bake quality? They partner with Reading Bakery Systems. We build equipment and complete systems that help large bakeries keep bake quality steady by controlling the steps that influence it most. When the process is designed to repeat results, your team can spend less time chasing problems and more time producing with confidence.

When a bakery gets big, quality control gets harder, not easier. You might have multiple lines, shifts, and plants, all trying to hit the same color, texture, and moisture targets every single day. How do large bakeries maintain consistent bake quality? They partner with Reading Bakery Systems. We build equipment and complete systems that help large bakeries keep bake quality steady by controlling the steps that influence it most. When the process is designed to repeat results, your team can spend less time chasing problems and more time producing with confidence.

Consistency Starts Before the Oven

If bake quality is drifting, the oven usually gets blamed first. But most quality swings begin upstream. If the dough varies from run to run, the oven can’t magically fix it. You’ll see it in spread, thickness, color pickup, and texture, and operators end up reacting instead of running the line.

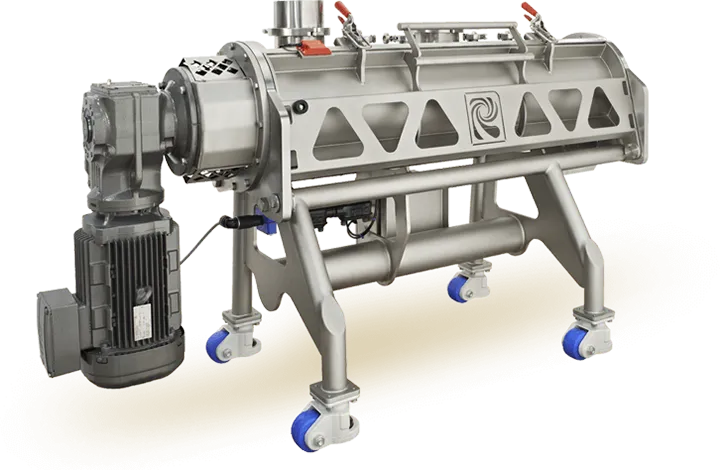

That’s where our mixing solutions come in. We offer continuous mixing systems that are built to produce a steady stream of consistent dough, which helps downstream steps behave more predictably. When dough consistency improves, you’re not constantly compensating at makeup or changing oven settings just to stay within spec. It’s a calmer way to run, especially when production schedules are tight.

Even Baking Comes From Better Heat Control

Once dough is consistent, the next big challenge is heat balance. Large bakeries don’t just need an oven that gets hot. They need an oven that stays even, zone after zone, hour after hour, so the product exits with the same bake profile every time.

We support that goal with oven technologies designed for industrial baking, including systems under our Thomas L. Green brand. If your operation is focused on crackers and biscuits, the Emithermic XE Oven is a good example of how modern oven design can support consistent results while also aiming for a simpler operating experience. The long-term win is fewer mid-shift corrections and fewer surprises when you change products or run longer campaigns.

Repeatability Across Plants Comes From Standardized Systems

If you’re running more than one facility, the toughest part is getting Plant Two to match Plant One. You can share a recipe, but you can’t always share the same operator instincts, the same shift habits, or the same workarounds. That’s where standardized equipment and process design make a difference.

We help large bakeries build repeatable lines by aligning mixing, handling, and baking into one coordinated approach. When the process is consistent by design, you’re not relying on tribal knowledge to keep quality steady. Training gets easier, quality targets become more realistic, and your brand standards stop feeling like a moving target from site to site.

See Why So Many Bakeries Put Their Trust in Us

When considering how large bakeries maintain consistent bake quality, they turn to products from Reading Bakery Systems. When mixing is steadier, dough behaves more predictably. When oven performance is balanced, color and texture stay on target. When handling and line flow are designed for stability, the finished product keeps its look and integrity.

If you’re aiming to tighten bake quality across multiple lines or multiple plants, we’ll help you look at the full process and match the right system elements to your goals, so consistency becomes the default instead of a daily fight. Get in touch by contacting us online or calling 610-693-5816.