When your line is humming, the entire plant feels lighter. When it’s not, every minute costs money and momentum. That’s why great equipment isn’t enough by itself – the best industrial bakery equipment suppliers in North America stand behind the steel with fast, practical, and ongoing support. At Reading Bakery Systems, we build ovens, mixers, and pretzel systems that run for decades, but we also show up with the know-how to keep them running like day one. If you’re choosing a partner, make tech support part of the spec. It’s the difference between “installed” and “performing.”

When your line is humming, the entire plant feels lighter. When it’s not, every minute costs money and momentum. That’s why great equipment isn’t enough by itself – the best industrial bakery equipment suppliers in North America stand behind the steel with fast, practical, and ongoing support. At Reading Bakery Systems, we build ovens, mixers, and pretzel systems that run for decades, but we also show up with the know-how to keep them running like day one. If you’re choosing a partner, make tech support part of the spec. It’s the difference between “installed” and “performing.”

Downtime Is Expensive – Support Is Cheaper

Every unexpected stop ripples from the mix room to packaging. A seized bearing, a drifting temperature loop, or a recipe that won’t behave at scale can burn a shift before lunch. Robust technical support turns big problems into small interruptions. We staff dedicated service teams, stock critical parts, and prioritize rapid troubleshooting so your ovens, continuous mixers, and forming equipment get back to work quickly.

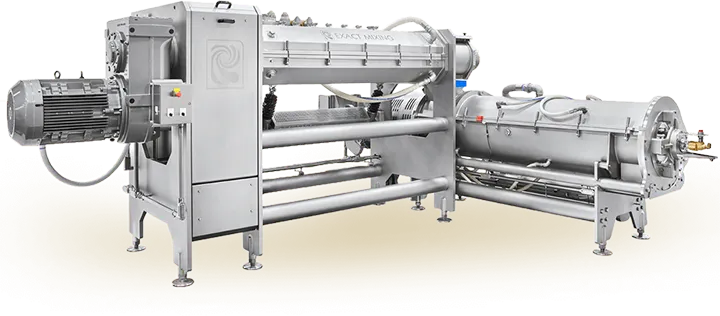

Whether you’re running a Thomas L. Green PRISM oven, an Emithermic XE electric oven, an Exact Mixing continuous system with Hydrobond™ Technology, or a Reading Pretzel line, our goal is simple: cut time to solution and protect your throughput.

Support That Starts Before Start-Up

The best service call is the one you never need. We begin support long before your first run – helping you size the right mixer for your doughs, choose oven zones that match your color and moisture targets, and plan line layouts that reduce changeover pain. At our Science & Innovation Center, we invite your team to trial formulas on real equipment, gather data, and leave with dialed-in settings. By de-risking the launch with hands-on tests, we help you hit spec faster and avoid the “teething” period that eats weeks on new lines.

Training That Sticks Across Shifts

Even great equipment can struggle if operators are guessing. We treat training as part of the deliverable, not an optional extra. Your team learns how to read the mixer, recognize when dough development is right, and adjust oven setpoints. We also work with maintenance crews on preventative tasks – band tracking, fan checks, lubrication, and sensor calibration – so small issues don’t become emergency stops. When people understand why a setting matters, they keep your product on target and your waste low.

Help On Day One – and Day 1,001

A bakery evolves. New SKUs arrive. Ingredient specs shift. Energy costs change the calculus. We stay in the picture with line audits, recipe tune-ups, and upgrade paths that extend useful life. If you’re scaling from batch to continuous, we can add an Exact EX, MX, or HDX mixer where it relieves the bottleneck.

If you prioritize lower emissions or tighter color control, we’ll look at Emithermic XE options, insulation improvements, or controls enhancements on your existing oven. And when pretzel demand spikes, our Reading Pretzel systems team can advise on forming capacity and drying balance so texture holds while output climbs.

Real Answers

You’ve seen the other version of support – tickets that bounce around while product piles up. We prefer clear ownership and practical fixes. Our technicians carry the knowledge of our platforms and the field experience to apply it quickly. The aim is always the same: solve the root cause and get you back to steady state.

Call Reading Bakery Systems at 610-693-5816 or contact us online. We’ll show you why we’re the leader among industrial bakery equipment suppliers in North America.