Before anyone talks price or lead time, industrial bakery equipment suppliers in Reading Bakery Systems should prove their process. That means showing how dough behaves, how heat is delivered, and how settings repeat across shifts. We invite teams to our Science & Innovation Center to run real formulas on our products. Seeing hydration, energy input, and temperature control in action beats a brochure every time. If a partner won’t put dough in a mixer and product in an oven before you sign, keep looking.

Before anyone talks price or lead time, industrial bakery equipment suppliers in Reading Bakery Systems should prove their process. That means showing how dough behaves, how heat is delivered, and how settings repeat across shifts. We invite teams to our Science & Innovation Center to run real formulas on our products. Seeing hydration, energy input, and temperature control in action beats a brochure every time. If a partner won’t put dough in a mixer and product in an oven before you sign, keep looking.

Show The Layout, Not Just The Machine

Great equipment can stumble in a poor layout. Upfront, you should see a thoughtful floor plan with people flow, sanitation paths, ingredient handling, utilities, and future expansion zones. We model lines so that mixers, proofers, ovens, and coolers are balanced, and we flag access points for sanitation and maintenance. Because our products feature industry-leading technology, we’ll also show where tomorrow’s capacity or new SKUs could land without rebuilding the plant.

Put Controls And Data On The Table

Controls aren’t a footnote; they’re the user experience. A supplier should demo a live HMI with recipe governance, alarm handling, and trend views you’d actually use on a Friday night. We walk through our controls environment and remote support so you can see how operators load recipes, how maintenance reads diagnostics, and how our team can securely help you troubleshoot. If you can’t touch it and click through it now, you’ll be learning under pressure later.

Hygiene, Changeover, And Cleaning Time In Writing

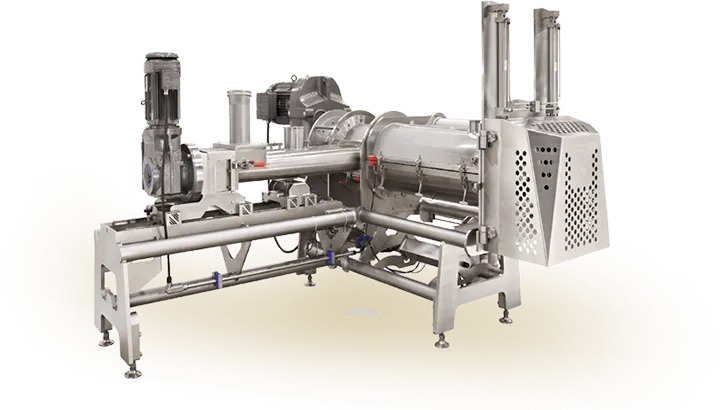

Uptime lives and dies on sanitation windows. A worthy supplier will show sanitary design details and the cleaning sequence that proves them out. We design continuous mixing equipment for cleanability and show you how our products make visual inspection straightforward. We’ll talk through realistic cleaning times so your multi-SKU plan isn’t a spreadsheet fantasy.

Service, Training, And Parts Without Fine Print

Support should be visible before a PO is issued. You deserve to see training outlines, spare parts recommendations, and response commitments in plain language. We map operator and maintenance curricula to your team, set up parts strategies that fit your risk profile, and back it with our RBS EZone, so many issues are solved in hours, not days. When you know how support works up front, there are fewer “wish we’d asked” moments later.

Performance And Sustainability You Can Measure

Claims are easy; targets are better. A supplier should share the metrics they’re willing to stand behind – throughput ranges, energy expectations, waste targets, and product specs like color bands or moisture loss. For example, we can discuss how the heat delivery of our Emithermic XE Oven supports uniform bake at efficient utility usage and how the loss-in-weight dosing of our mixing equipment reduces giveaway and water waste.

A Place To Prove It Before You Buy

We encourage side-by-side trials – altering hydration, staging energy, and adjusting oven profiles – so your production team leaves with a validated playbook. That hands-on work accelerates commissioning because the “golden batch” isn’t a moving target; it’s a documented recipe with known setpoints.

If It Matters Later, See It Now

The best industrial bakery equipment suppliers in South America show process proof, real layouts, live controls, credible schedules, sanitation realities, service depth, and measurable performance before you commit. That’s how we operate at Reading Bakery Systems. You can contact us online or call +1 610-693-5816 for more information.