Price swings, long-lead electronics, and shipping hiccups can derail a bakery project before the first sheet of dough hits the line. The industrial bakery equipment suppliers in Turkey, such as Reading Bakery Systems, start by mapping risks with you instead of treating delays as “acts of nature.”

Price swings, long-lead electronics, and shipping hiccups can derail a bakery project before the first sheet of dough hits the line. The industrial bakery equipment suppliers in Turkey, such as Reading Bakery Systems, start by mapping risks with you instead of treating delays as “acts of nature.”

Design For Flexibility From Day One

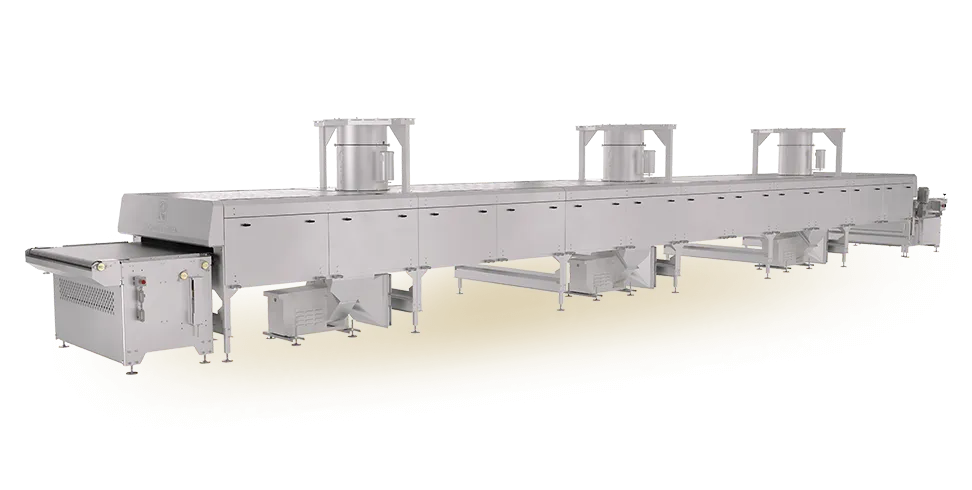

Modular frames, universal mounting points, and service-friendly access let your line accept alternative components without major rework. We engineer our continuous mixing systems and ovens so you can adjust capacity or swap options without rewriting the whole plant layout. If you decide to add another ingredient stream, change a proofing window, or expand oven zones later, you’re not starting over – you’re building on what’s already there.

Standardize Controls And Parts To Reduce Exposure

Nothing hedges better than parts you already stock. We standardize controls across our platforms – mixers, ovens, and downstream systems – so operators see the same logic and maintenance teams draw from a tighter, more familiar spares list. Recipe governance and diagnostics live in a consistent controls environment, which means a PLC card or HMI can serve multiple assets. When you don’t need 10 versions of everything, a supply chain wobble is an inconvenience, not a crisis.

Use Data And Remote Support To Keep Running

Volatility isn’t just about getting equipment installed; it’s also about staying productive when service travel or parts availability is limited. Our remote support lets us diagnose issues, push safe parameter updates, and guide your team through fixes without waiting on a flight. Many of our advanced products stream key data – ingredient feed rates, dough temperature, and energy input, etc. – so you can adjust to raw material variability when your preferred flour or fat source shifts. Real-time insight beats “we’ll see at startup” every time.

Build A Service Plan That Actually Shields You

Spare parts strategy is a hedge, not a cost center. We help you identify critical spares and set up replenishment so every hour saved helps boost your profit margin. Training is part of that plan. Because our platforms share a common controls philosophy, cross-training operators and maintenance techs is straightforward, which reduces reliance on any single expert. If a supplier delay bumps an on-site visit, your team isn’t stuck – they’re equipped to keep the line moving.

Keep Sustainability And Efficiency In The Conversation

Volatile utilities are part of the supply chain story. The Emithermic XE Oven is designed for uniform baking with efficient heat use, and our continuous mixers meter ingredients precisely to reduce giveaway and water waste. When energy and ingredient markets bounce around, equipment that sips rather than gulps is its own hedge, protecting both margins and sustainability goals.

Helping Your Company Maintain a Healthy Bottom Line

Hedging against supply chain volatility isn’t about luck; it’s about structure. At Reading Bakery Systems, we’ve built our service model to turn uncertainty into manageable variables. If you’re planning a project in a world that refuses to sit still, we can engineer a line – and a schedule – that can handle the bumps and keep you baking consistently.

We invite you to learn more about what makes Reading Bakery Systems a leader among industrial bakery equipment suppliers in Turkey. You can give us a call at +1 610-693-5816, or you can use our online form.