If you’ve ever chased dough variation across shifts, you know how painful “pretty close” can be. One batch looks great, the next one runs heavy, and suddenly you’re tweaking makeup settings just to stay on spec. Continuous mixing flips that script. Instead of starting and stopping, it creates a steady stream of dough with the same hydration, temperature, and development – minute after minute. Industrial mixing equipment for bread production lines from Reading Bakery Systems can ensure more efficient production, tighter quality, and real throughput gains.

If you’ve ever chased dough variation across shifts, you know how painful “pretty close” can be. One batch looks great, the next one runs heavy, and suddenly you’re tweaking makeup settings just to stay on spec. Continuous mixing flips that script. Instead of starting and stopping, it creates a steady stream of dough with the same hydration, temperature, and development – minute after minute. Industrial mixing equipment for bread production lines from Reading Bakery Systems can ensure more efficient production, tighter quality, and real throughput gains.

The Consistency Advantage Starts At The Feeder

Great dough starts with accurate ingredients. In a batch world, small weighing errors add up, and you don’t notice until the bowl tips. With continuous mixing, high-accuracy feeders meter flour, water, and minor ingredients at a constant rate, so your formula isn’t a point-in-time event–it’s a controlled process. We design our Exact Mixing lines so ingredient flow, mixer torque and dough temperature stay in a tight window. That means fewer mid-shift surprises and less fiddling downstream at the divider, sheeter, or wirecut.

Uniform Hydration, Every Second

Hydration is where dough is won or lost. Lumps, dry pockets, and over-wet streaks all come from uneven water contact. Our Hydrobond Technology instantly combines dry and liquid phases before they enter the mixer, creating a uniform, fully hydrated mass. Because particles meet water the same way every second, you get shorter mix times, less friction heat, and dough that arrives at the same temperature run after run.

Develop The Dough You Want – Not Averages

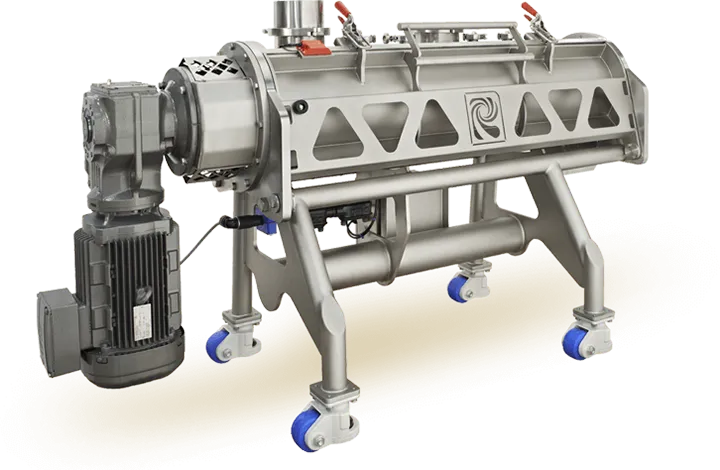

Batch mixing often swings between underdeveloped and overworked. Continuous mixing lets you tune development precisely to the product. Our Exact Mixing portfolio gives you the right tool for the job:

- The EX Continuous Mixer for low-to-mid development doughs like crackers, pretzels, and snacks.

- The MX for mid-to-high development applications.

- The HDX for ultra-high development breads, buns and pizza.

- The FX for high-hydration slurries and batters.

We match mechanical action and residence time to your target structure, so the dough behaves at makeup and bakes the way you promised.

Hygiene And Safety Designed In

Continuous doesn’t mean complicated. We engineer Exact Mixing lines with open frames, accessible contact parts, and automated cleaning routines where they make sense, so crews can clean thoroughly and get back to production quickly. Fewer manual touches around open ingredients reduces risk and keeps allergen control straightforward. It’s a smarter way to keep people safe and programs audit-ready.

Try It On Your Products

The best way to see the difference is to run your formulas on our equipment. In our Science & Innovation Center, we’ll dial in feed rates, hydration, and energy input on the exact mixer model that fits your application, then carry the dough to forming and baking on Thomas L. Green or Reading Pretzel lines. You leave with data, samples and a clear path to scale – no guesswork, no “trust us.”

Make Consistency Your Default

Batch mixing can work, but it makes consistency a daily battle. Continuous mixing turns it into your default setting. If you’re ready to feel the difference on your floor, use our online form or call Reading Bakery Systems at 610-693-5816 to learn more about our industrial mixing equipment for bread production lines. We very much look forward to working with you.