Hot dog buns seem simple, but the dough behind a great bun is picky. It wants enough strength to hold shape, enough tenderness to feel soft on day three, and consistent gas cells so the crumb isn’t tight in one bite and airy in the next. All of that starts with the mixing profile – the way you combine time, energy, and hydration to develop gluten and manage temperature. Reading Bakery Systems industrial mixing equipment for hot dog bun production lines can help you achieve the optimum profile – helping you run fast without trading quality for speed.

Hot dog buns seem simple, but the dough behind a great bun is picky. It wants enough strength to hold shape, enough tenderness to feel soft on day three, and consistent gas cells so the crumb isn’t tight in one bite and airy in the next. All of that starts with the mixing profile – the way you combine time, energy, and hydration to develop gluten and manage temperature. Reading Bakery Systems industrial mixing equipment for hot dog bun production lines can help you achieve the optimum profile – helping you run fast without trading quality for speed.

Why Mixing Profiles Matter For Bun Quality

A “mixing profile” isn’t just a time setting. It’s the sequence of hydration, development, and temperature control that shapes the dough’s behavior downstream. For hot dog buns, you’re balancing extensibility (to flow through dividers and moulders) with resilience (to spring in the oven and hold the classic hot-dog shape). Too little energy and you’ll get weak dough, poor volume, and uneven crowns. Too much and you’ll over-tighten the gluten, trap heat, and end up fighting short proof windows and split tops. The profile is how you call the shots before the line ever sees a divider.

Defining Your Profile: Hydration, Energy, And Temperature

Start with hydration. Most bun formulas respond best when water meets flour quickly and evenly. If that water doesn’t arrive soon enough or is poorly distributed, you’ll chase clumps and see inconsistent absorption. Next comes energy. It’s not only how long you mix – it’s how the mixer applies shear and how that energy is staged.

Many plants do better with an initial incorporation phase, a development phase to build structure, and a brief finish to stabilize the dough. Temperature rides alongside both steps. Keeping dough cool preserves yeast performance and protects proofing flexibility. As throughput climbs, heat from friction adds up, so jacketed equipment and controlled water temperatures become essential.

Continuous Mixing That Keeps Pace

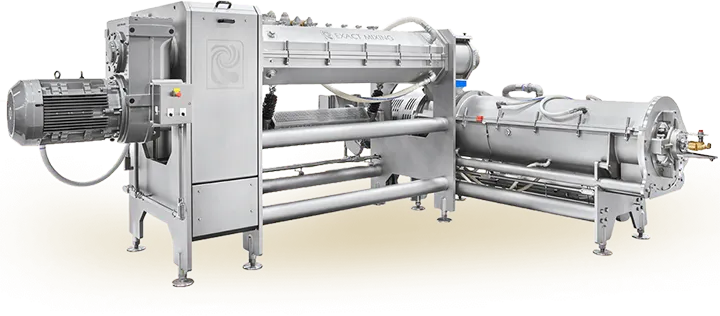

This is where we shine. We bring continuous mixing to high-throughput bun operations so you can lock in a profile that repeats hour after hour. Our HDX Continuous Mixer, for example, is engineered for fully developed doughs like hot dog buns, delivering the energy needed for strength while managing dough temperature with jacketed sections and precise water dosing.

Because ingredients feed in with loss-in-weight accuracy, you get consistent ratios from the first kilogram to the last, even through long runs and shift changes. The result is steady rheology, reliable scaling at the divider, and fewer surprises at the proofer.

Tuning The Details Without Slowing The Line

Production realities change: seasonal flour swings, minor ingredient substitutions, or tighter proof schedules. We build flexibility into the system so you don’t have to throttle speed to protect quality. Our controls let you fine-tune setpoints for hydration rate, dwell time, and development energy while watching dough temperature in real time.

If you’re targeting a softer bite or a little more baked height, you can adjust the profile instead of rewriting the formula. Add-on features like inline cooling and controlled additions for oil or emulsifiers help you fine-tune crumb tenderness without creating “grease-out” or weak structure.

Please don’t hesitate to learn more about our industrial mixing equipment for hot dog bun production lines by calling Reading Bakery Systems at 610-693-5816 or contacting us online.