Low-pressure extrusion is all about shape fidelity and texture – twists, sticks, braids, and other profiles that need dough to behave. If viscosity wobbles, the die will tell on you with swelling, seam splits, or ragged cut edges. The cleanest fix isn’t more backpressure or a slower line; it’s a steadier dough stream. That’s where continuous mixing industrial mixing equipment for snack production lines from Reading Bakery Systems shines.

Low-pressure extrusion is all about shape fidelity and texture – twists, sticks, braids, and other profiles that need dough to behave. If viscosity wobbles, the die will tell on you with swelling, seam splits, or ragged cut edges. The cleanest fix isn’t more backpressure or a slower line; it’s a steadier dough stream. That’s where continuous mixing industrial mixing equipment for snack production lines from Reading Bakery Systems shines.

Continuous Mixing Makes Stability Boring (And That’s Good)

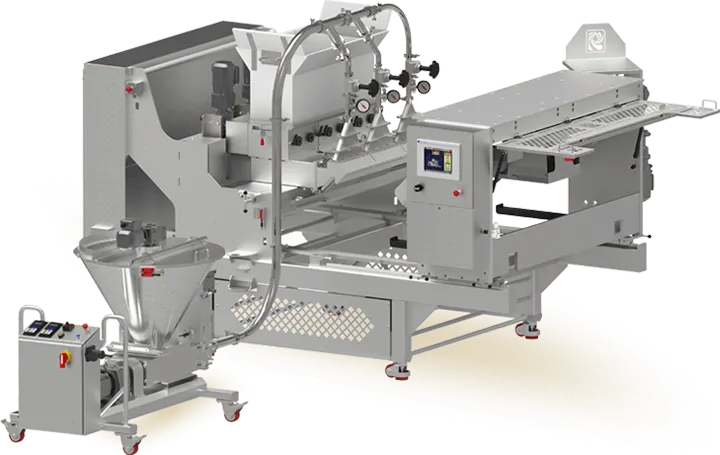

At Reading Bakery Systems, we design our continuous mixing products to take the drama out of dough. We meter dry and liquid ingredients with loss-in-weight accuracy, hydrate fast and uniformly, then apply measured energy so gluten develops to the level your product needs – no more, no less.

For low-pressure extrusion, that consistency is everything. Smoothness and repeatability translate to strands that hold dimension, corners that stay sharp, and cuts that look crisp instead of torn. When dough is boringly stable, your operators can focus on throughput and quality checks rather than firefighting.

Match The Mixer’s Rhythm To The Extruder’s Appetite

A great extruder can’t fix a choppy feed. We pair the output of our continuous mixing equipment to your low-pressure extruder’s demand so the die never starves and never gets flooded. That includes buffering strategies, smart auger handoffs, and controls logic that keeps mass flow steady when you accelerate or decelerate the line. If your product mix includes different hydration levels or salt loads, recipe governance ensures the right profile arrives at the die every time – without late-stage tweaks that add heat or create variability.

Hydration, Energy, And Temperature

Stable extrusion starts with fast, thorough hydration. We design our systems to wet flour quickly so you’re not chasing dry pockets downstream. Next comes energy input. For pretzel and cracker-style doughs headed to a low-pressure die, we focus on development that supports shape without turning the dough rubbery.

Finally, temperature control protects yeast performance when used and prevents friction from creeping dough out of spec. Jacketed sections and controlled ingredient temperatures help keep the process in that “easy to extrude” zone where the die face stays clean and the strand surface looks smooth.

When Formulation Shifts, Controls Keep You Centered

Flour changes, water quality wobbles, and ambient conditions don’t always cooperate. Our controls give you live visibility into feed rates, torque indicators, and dough temperature, then let you make small, confident adjustments. They can provide a touch more water, a nudge in dwell time, or a slight energy change without derailing the run.

Because settings are recipe-driven, cross-shift performance holds steady, and training gets simpler. Add RBS EZone remote support, and our engineers can help you diagnose trends and coach adjustments without waiting for a site visit.

Proving It Before You Scale

You don’t have to guess how a profile will behave at the die. Bring your formulas to our Science & Innovation Center and pilot them on our continuous mixing equipment. Together, we’ll map hydration curves, define development windows, and observe strand quality and cut behavior in real time. You’ll leave with a validated playbook that translates to the plant floor, making the first production day immediately feel like it’s second nature.

If you would like to put our industrial mixing equipment for snack production lines to the test, please call Reading Bakery Systems at 610-693-5816 or contact us online.