If you’re trying to push more product through the plant without inviting headaches, steady-state mixing is one of the cleanest wins. What efficiency gains can bakeries expect from continuous mixing products from Reading Bakery Systems? Bigger gains than you might have imagined possible. Instead of stopping to load, mix, unload, and clean a bowl every cycle, ingredients flow in and developed dough flows out at a constant rate. That alone removes a lot of waiting and juggling. Or Exact Mixing portfolio helps bakeries turn that steady flow into real, everyday efficiency.

If you’re trying to push more product through the plant without inviting headaches, steady-state mixing is one of the cleanest wins. What efficiency gains can bakeries expect from continuous mixing products from Reading Bakery Systems? Bigger gains than you might have imagined possible. Instead of stopping to load, mix, unload, and clean a bowl every cycle, ingredients flow in and developed dough flows out at a constant rate. That alone removes a lot of waiting and juggling. Or Exact Mixing portfolio helps bakeries turn that steady flow into real, everyday efficiency.

Where the Time Savings Come From

Batching steals time in small pieces: staging ingredients, lowering a bowl, scraping sides, transferring tubs, and restarting downstream equipment. In a continuous setup, those pauses disappear. Dry and liquid streams are metered automatically, development happens at a controlled state, and the sheeter or depositor gets a predictable handoff. Lines simply stay “in the groove” longer. We see the biggest scheduling lift when plants run families of similar SKUs; the mixer doesn’t need to ramp up and down, so you get more sellable minutes per shift.

Consistency That Quietly Cuts Waste

Speed only helps if the dough behaves. Because continuous systems hold ratios, temperature, and mechanical energy steady, the first minute of production looks like the five-hundredth. That consistency shows up as fewer sheet thickness adjustments, less chasing of oven setpoints, and a tighter moisture target at packaging.

Hydrobond Technology gives you a further boost by wetting powders instantly and evenly before the mixing chamber. When hydration is that uniform, you avoid pockets of over- or under-worked dough, which helps color, lift, and bite stay on brand while scrap and rework go down.

Changeovers And Sanitation Without The Drama

Nobody wants changeovers to be the longest meeting of the day. Continuous mixing simplifies them because there’s no bowl to empty and clean between each run. Ingredient streams are enclosed and controlled, which helps with allergen management and keeps the room cleaner. Because our systems are designed for quick verification, operators can prove the line is ready and start making good dough faster. Less idle time between SKUs is an efficiency gain that adds up across a week.

Match The Mixer To The Products

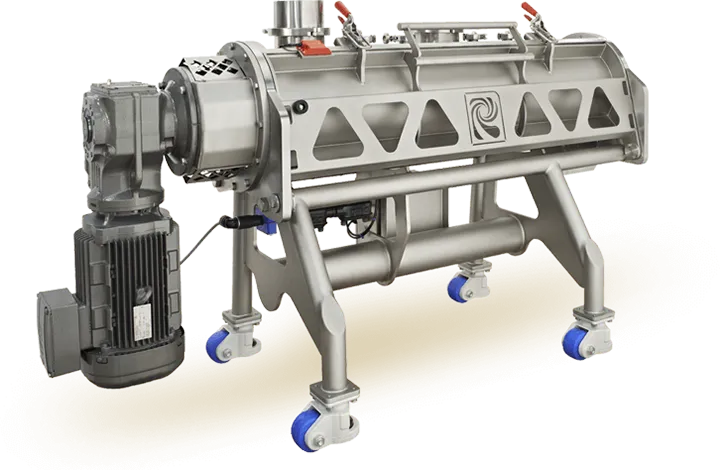

Choosing the right tool is part of the efficiency story. Our EX Continuous Mixer is a go-to for wheat-based snacks and crackers where gentle development and temperature control matter. For ultra-absorption formulas like buns, rolls, and tortillas, the HDX High Development Mixer uses two stages to build strength at lower dough temperatures – so you don’t spend energy cooling problems you created upstream.

For low-moisture, powder-heavy items such as fabricated chips, the FX Continuous Mixer uses high-speed mixing to lift powders into atomized liquid for clean, fast hydration. When the mixer fits the job, you spend less time adjusting and more time producing.

Easier Days For Operators (and Maintenance)

Efficiency isn’t only throughput; it’s how calmly a shift runs. A stable dough stream means fewer surprise interventions, fewer stops for “mystery texture,” and a smoother warm-up after breaks. Operators can focus on the line instead of firefighting the mix.

Maintenance teams benefit, too. With fewer mechanical start-stops and less tub handling, wear and tear drops. Our controls make it simple to capture the settings that worked best, so the next run starts from a proven recipe – not from scratch.

What efficiency gains can bakeries expect from continuous mixing? As you can see, they’re substantial when you turn to Reading Bakery Systems products. Call 610-693-5816 or use our online form for more information.