The wide variety of industrial pet treat equipment and machines from Reading Bakery Systems can handle your dog biscuit making process and help you reduce operating costs.

Reading Bakery Systems, headquartered in Robesonia, Pennsylvania, is a world leader in the manufacture of commercial bakery equipment. Our experience with pet treats comes from more than 120 years of developing proven solutions in the global snack food industry.

Mixing

If your dough suffers from undesirable variations from batch to batch, one of the first improvements you can make is to switch from batch mixing to continuous mixing.

Continuous Mixing offers many advantages over batch mixing, particularly in the ability to produce more consistent dough with less labor and energy.

The Exact EX Continuous Mixer is ideal for both soft, chewy and hard, crunchy dog biscuits and pet treats. It uniformly mixes products with a variety of dough moisture levels.This mixer offers dough production rates from 50 to 10,000 kg/hour.

The dough is mixed well and quickly heated to the proper kill temperature within a range of 1 degree and then cooled.This is done automatically and with no handling or manual transporting of the dough.

Dough Forming

Moulded Products: For rotary moulded pet treats, the Thomas L. Green Rotary Moulder efficiently produces high definition, three dimensional shapes by pressing dough into a die roll.

Extruded Products: For extruded and co-extruded products, the Reading Pretzel Low Pressure (LP) Extruder enables consistent and accurate production of a variety of structural, flat and filled extruded shapes and sticks.

Sheeted Products: For sheeted pet treats, the Thomas L. Green Sheeter generates a consistent dough sheet, and Gauging Stations ensure a gentle reduction in sheet thickness prior to shape forming. Scrapless geometric shapes and distinct shapes can be formed by the Rotary Cutting Station.

Guillotine Cutter: For sticks and nuggets, the single-blade Guillotine Cutter is used to cut products uniformly before or after baking, allowing the operator to create a product size as short as one inch (25 mm) at the press of a button.

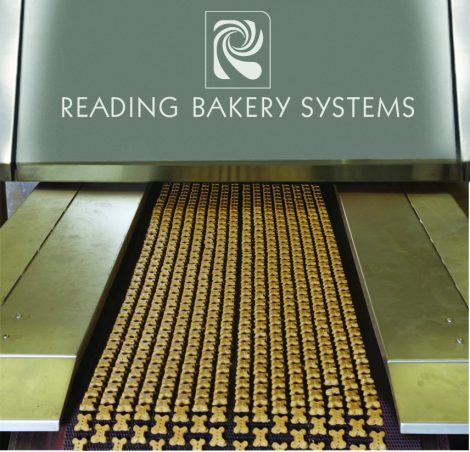

Baking & Drying

Reading Pretzel SPECTRUM OVEN® customers benefit from balanced and consistent baking of dog biscuits and pet treats.. The single pass convection baking platform offers customers more precise control of product quality and features:

- Radiation, convection and conduction heat transfer options

- Separate heating zones for more precise control

- Repeatable control of time, temperature, humidity and type of heat transfer

- Stainless steel interior construction

Add a separate optional SPECTRUM Multi-Pass Dryer for faster oven speeds, greater production throughput, and more process control. The Dryer efficiently reduces product core moistures, improving overall quality and storage characteristics.

To experience the advantages of the world’s most advanced industrial pet treat equipment and dog biscuit making machines from Reading Bakery Systems, click here or call us at (01) 610-693-5816.