Discover the continuous mixing, forming, baking and drying pet food manufacturing equipment available from Reading Bakery Systems that can help you improve your process and products.

Reading Bakery Systems, headquartered in Robesonia, PA, is a leading manufacturer of industrial bakery equipment. We serve the biscuit, cookie, cracker, pretzel, baked snack and pet food/treat industries. With more than 120 years of commercial baking experience, we help customers around the globe meet their production challenges and take their pet food manufacturing to the next level.

Continuous Mixing Technology

If your pet food dough suffers from undesirable variations from batch to batch, switch from batch mixing to continuous mixing. Continuous Mixing offers many advantages over batch mixing, particularly the ability to produce more consistent dough with less labor and energy.

The Exact EX Continuous Mixer is ideal for both soft, chewy and hard, crunchy pet food. It uniformly mixes products with a variety of dough moisture levels.This mixer offers dough production rates from 100 to 10,000 kg/hour.

Product Forming Solutions

Whether you are producing pet food that is rotary molded, extruded, sheeted, or in stick or nugget form, Reading Bakery Systems offers a solution to meet your requirements.

- Rotary Moulded: The Thomas L. Green Rotary Molder produces high definition, three dimensional shapes by pressing dough into a die roll. Engraved brass die rolls are interchangeable and can be supplied with segmented rings for simultaneous, multiple shape production.

- Extruded: The Reading Pretzel Low Pressure (LP) Extruder allows you to produce consistent and accurate structural, flat and filled extruded shapes and sticks. Fit with different compression heads and dies to broaden your product range.

- Sheeted: The Thomas L. Green Sheeter creates a consistent dough sheet for sheeted pet food products, and Gauging Stations ensure accurate thickness prior to shape forming. Scrapless geometric shapes and distinct shapes can be formed with the Rotary Cutting Station.

- Sticks/Nuggets: The single-blade Reading Pretzel Guillotine Cutter uniformly cuts products before or after baking, allowing the operator to create a product size as short as one inch (25 mm) at the press of a button.

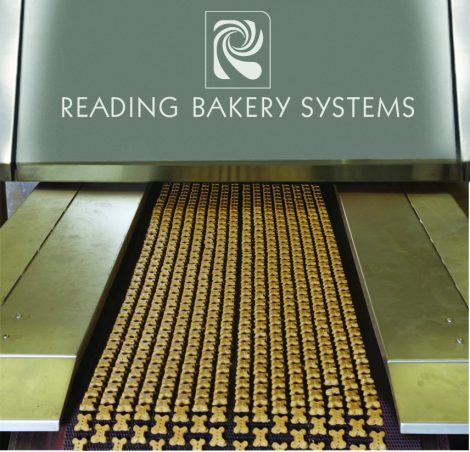

Baking & Drying Equipment

With the Reading Pretzel SPECTRUM OVEN®, customers benefit from a variety of heat transfer combinations in one modular design. The single-pass convection baking platform features operator-controlled air temperature, circulation speed, exhaust, and moisture removal for reliable, consistent baking of pet treats. The addition of an optional SPECTRUM Multi-Pass Dryer will increase oven speed, production throughput and process control.

To explore our innovative equipment or learn how to improve your pet food production process, consider working with our team in the Reading Bakery Systems Science & Innovation Center, where you can test the latest new machinery and processing techniques, duplicate conditions you might encounter in full-scale production, change and test ingredients in your products, and develop new pet food products.

When you need the best tools to stay ahead of pet treat and pet food market demands, innovative equipment from Reading Bakery Systems will handle all aspects of your manufacturing process. Call us at (01) 610-693-5816 or click here to learn more.