Reading Bakery Systems manufactures cost-effective mixing, dough handling, dough forming, baking and drying equipment for every part of your pet treats production line.

Headquartered in Robesonia, Pennsylvania, Reading Bakery Systems (RBS) serves customers in the global snack food industry, providing high-quality equipment for the production of stackable potato chips, baked potato chips, baked crisps, and other products such as crackers, biscuits, pretzels, bread snacks, pet treats and more.

With more than 120 years of expertise and an unmatched range of equipment, customers rely on our technologically advanced mixing, forming and cutting equipment to improve efficiency, quality, volume and profitability.

If you are new to the pet treat industry or want to explore methods of improving your volumes or production processes, consider working with our team in the Reading Bakery Systems Science & Innovation Center.

The Center gives customers access to our unrivaled expertise in manufacturing, research and development, quality assurance, equipment design, production management, and process development, as well as assistance in die design and custom equipment development.

Mixing Equipment

The Exact EX Continuous Mixer will help you produce more consistent dough with less labor and energy, a major advantage over batch mixing. The mixer is well-suited to both soft/chewy and hard/crunchy pet treats.

Dough can be quickly heated to the proper kill temperature within a range of 1 degree and then cooled. This is done in the mixer automatically and without additional dough handling. Dough delivery can be automated with a mini-laytime conveyor and chunker or kibbler attachments.

Forming Equipment

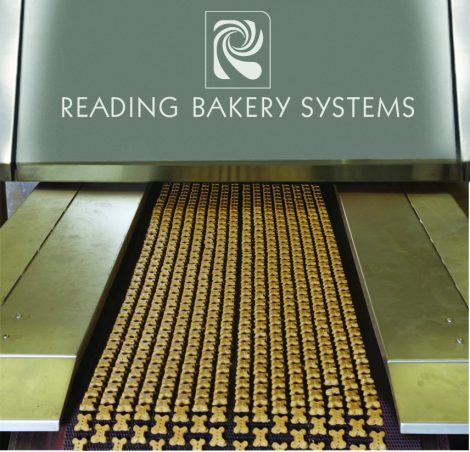

Whether your pet treats are rotary moulded, extruded, sheeted, or in stick or nugget form, Reading Bakery Systems offers a solution that is designed and engineered to meet your needs.

Rotary Moulded: The Thomas L. Green Rotary Moulder produces high definition, three-dimensional shapes by pressing dough into a die roll. Engraved brass die rolls are interchangeable and can be supplied with segmented rings for simultaneous, multiple shape production.

Extruded: With the Reading Pretzel Low Pressure (LP) Extruder, you can produce consistent and accurate structural, flat and filled extruded shapes and sticks. Fit the Extruder with different compression heads and dies to expand your product range.

Sheeted: The Thomas L. Green Sheeter creates a consistent dough sheet for sheeted pet treats, and Gauging Stations ensure accurate thickness prior to shape forming. Scrapless geometric shapes and distinct shapes can be formed with the Rotary Cutting Station.

Sticks/Nuggets: Use the single-blade Reading Pretzel Guillotine Cutter to uniformly cut products before or after baking. Operators can create products as short as one inch (25 mm) in size at the push of a button.

Baking & Drying Equipment

The Reading Pretzel SPECTRUM OVEN® offers a variety of heat transfer combinations in one modular design. The single pass convection baking platform is designed for balanced and consistent baking of dry pet food and pet treats. Add an optional SPECTRUM Multi-Pass Dryer for faster oven speeds, greater production throughput, and more process control.

Installing the right equipment in your pet treats production line can increase your efficiency and reduce costs without sacrificing the quality of your products. Call us at (01) 610-693-5816 to learn more or click here to contact us online.