When you manufacture extruded snacks, consider the world’s most advanced extrusion equipment from Reading Bakery Systems that will help you make an impressive visual presentation and distinguish your product from others on the market.

Reading Bakery Systems, headquartered in Robesonia, Pennsylvania, understands the dynamic nature of the global baked snack food industry, and has supplied efficient, reliable and cost-effective snack extrusion equipment to customers in the pretzel, baked snack, biscuit, cookie and cracker, and pet treat industries since 1947.

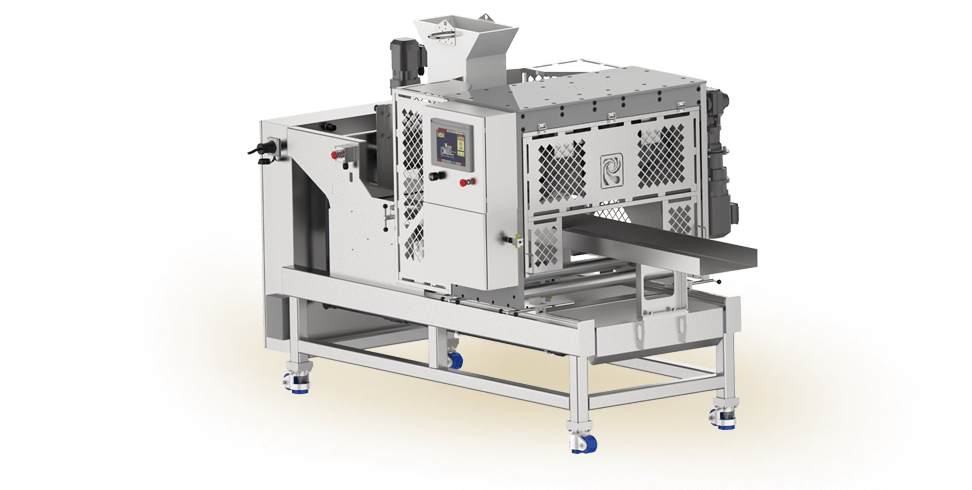

Low Pressure Extrusion

Create a wide variety of structural and flat extruded shapes with the Reading Pretzel Low Pressure (LP) Extruder. It allows for high-speed production of complex shapes by forcing dough through compression head and die assemblies and is a flexible alternative to conventional dough forming and sheeting systems.

The LP Extruder allows you to create many different snacks on a single production line, including hard pretzel shapes, sticks, braids, crackers, sushki and co-extruded products. Product changeover can be completed in just minutes by exchanging one compression head and die for another with a different shape.

The LP Extruder was recently redesigned with augers that deliver more product flow with less work; new lightweight, seamless hoppers that eliminate harborage areas; pre-feed rolls made of food-safe plastics; an improved cutting mechanism with a longer service life; improved guarding for better safety; and a bandcutter cam that is positioned away from the product zone to reduce contamination and provide easier maintenance.

Filled Stick Extrusion

Create sticks filled with soft fillings, such as cheese, chocolate or peanut butter, with the Reading Pretzel Filled Stick Extrusion System. A pump system pushes the soft filling through the compression head and die on the LP Extruder so that it fills the dough stick formed by the Extruder. The product rope can then be cut into equal length sticks or nuggets by the downstream Guillotine Cutter. Quick product changeovers can be accomplished by easily exchanging custom die and compression heads.

Fried Snack Extrusion

The Reading Pretzel Fried Snack Extruder produces flexible and innovative product shapes for fried snack extruded products, such as potato rings, potato sticks, and ethnic noodles. It is capable of processing up to 3,000 pounds (1500 kilograms) of dough per hour.

The extruded product is delivered to the fryer by a belted conveyor or by incorporating an optional oil “free float” conveying section. The Extruder with pre-feed rollers manages dough flow for optimum consistency from the time it enters the infeed hopper through being cut off at the die face by the high-speed bandcutter, which operates at up to 275 cuts per minute (cpm) or in cycle mode up to 50 cpm.

High Pressure Extrusion

The High-Pressure Extruder mixes and cooks ingredients to produce expanded shapes, including curls, popcorn shapes, rings, and balls. Its flexible design provides for quick and easy changeover of the screws, barrels and product dies, allowing for a wide variety of products with interesting textures and flavors in different shapes.

To learn more about Reading Pretzel’s flexible and cost-effective equipment that is designed to assist in your manufacture of extruded snacks, contact Reading Bakery Systems today at (01) 610-693-5816 or contact us online.