Features & Specifications

Additional Equipment Photos

See it in Action

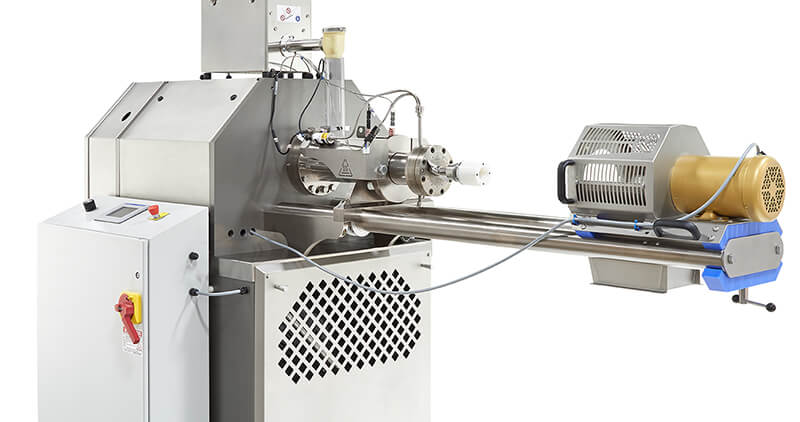

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

- Dies are interchangeable for multiple product

- Directional discharge chute for multi-line production

- Cutter assembly interlocked for operator interaction during production set up

Contact us for a full list of features and specifications.

RBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Automatic controls ensure operators are not exposed to moving parts

- Guards are designed to allow operator inspection during production

- Guards surrounding moving parts are electrically interlocked with the safety circuit

- Feeder can be electrically interlocked with the safety circuit

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

- Touchscreen based operator interface mounted locally or in conjunction with other equipment

- Extruder controls can be tied into a cascade system to automatically modulate production speeds throughout the production line