Improve the products in your commercial bakery in Italy, solve your production challenges, and maximize your profitability with the innovative and technologically advanced line of industrial bakery equipment from Reading Bakery Systems.

Reading Bakery Systems (RBS), headquartered in Robesonia, Pennsylvania, serves the biscuit, cookie, cracker, pretzel, baked potato chip, bread snack, sweet goods and pet treat industries. We can help you customize equipment and systems to meet your production demands.

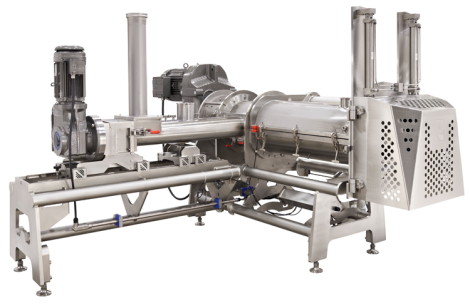

Continuous Mixing Technology

Continuous Mixing is the process of continuously metering ingredients directly into the mixing chamber to generate a continuous stream of mixed dough at the exit of the mixer. The mixing may be done in stages to ensure all ingredients are incorporated properly.

The advantages of continuous mixing include:

- Completely automated process

- High production rates with one mixer

- More precise delivery of raw materials to the mixer

- Consistent finished weight, size and texture

- Recipe control and repeatability

- Even dough hydration

- Quick and easy sanitation

- Can be operated with less labor and energy than batch mixing

Exact Continuous Mixers come in a variety of sizes, ranging from 50 to 10,000 kg/hour. Different models are available based primarily on dough moisture levels and number of mixing stages.

Use the Exact MX Continuous Mixer, our most versatile mixer, for a wide range of products including cookies, snacks, pizza, batters, icings, and pastes.

Use the Exact EX Continuous Mixer for low-absorption, stiff, wheat-based doughs, such as for crackers, bagels, pretzels, sweet goods and pet treats.

Use the Exact HDX Continuous Mixer for ultra-high absorption doughs for buns, breads, rolls, English muffins or tortillas.

Use the Exact FX Continuous Mixer, a high intensity mixer, to produce potato-, corn- and rice-based products and specialty baked snacks such as fabricated potato chips.

Dough Forming Solutions

When you need exceptional extrusion machinery that offers high quality and precision, the solutions from RBS are designed and engineered to meet your production needs.

The Reading Pretzel Low Pressure (LP) Extruder enables you to create a variety of structural and flat extruded and co-extruded shapes and sticks on one production line. It is a flexible alternative to conventional dough forming and sheeting systems.

The Reading Pretzel Filled Stick Extrusion System creates sticks filled with soft fillings, such as cheese, chocolate, and peanut butter. The product rope that is produced is cut into equal length sticks or nuggets by a downstream Guillotine Cutter.

Flexible, High-Quality Ovens

The Reading Pretzel SPECTRUM OVEN® offers radiation, convection and conduction heat transfer options in a single modular design, making it ideally suited for balanced and consistent baking of extruded pretzels and snacks, baked snack crisps from potato, wheat, multi-grain or corn masa flour doughs, and pet treats.

The Thomas L. Green PRISM OVEN has been trusted in the biscuit, cookie and cracker industry for more than a century. The flexible single-pass baking platform offers Direct Gas Fired (DGF) Zones, Emithermic (Radiant / Convection) Zones and Convection Zones.

Explore the complete range of Reading Bakery Systems industrial bakery equipment to meet your production needs in Italy. Contact our European Sales Manager, Joe Pocevicius, at +31-615-510-789, our U.S. headquarters at (01) 610-693-5816, or click here for more information.