Reading Bakery Systems is a world leader in the manufacture of technologically advanced industrial bakery equipment for customers in the snack food industry in South Africa and throughout the world.

Headquartered in Robesonia, Pennsylvania, USA, Reading Bakery Systems designs, engineers and manufactures the world’s most innovative equipment for the production of crackers, biscuits, baked potato chips, cookies, pretzels, bread snacks, baked crisps, pet treats and more.

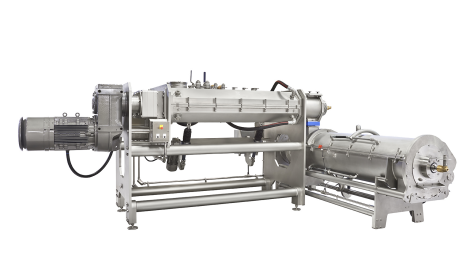

Continuous Mixing Innovations

Batch mixing can lead to dough variations that affect the consistency of your finished products.Continuous mixing has become more popular for its ability to continuously produce a more consistent dough.

The advantages of continuous mixing include:

- More precise delivery of raw materials to the mixer

- Improved consistency of weight, size and texture

- Elimination of dough troughs

- Recipe control and repeatability

- Completely automated process

Exact Continuous Mixers come in a variety of sizes, ranging from 50 to 10,000 kg/hour. Models include the Exact EX Continuous Mixer, which is ideal for crackers, pretzels, sweet goods, pet treats and other wheat-based products, and the Exact HDX Continuous Mixer, which is ideal for products such as buns, breads, English muffins and similar products, and is designed to manufacture highly developed dough at low temperatures.

Baking & Drying Innovations

The Thomas L. Green PRISM OVEN is a powerful system for uniform baking of products such as hard and soft biscuits, cookies, crackers, English muffins and snack cakes. It employs Direct Gas Fired (DGF) Zones, Emithermic (Radiant / Convection) Zones and Convection Zones, each with a number of options to provide your baked products with uniform quality, color, taste and texture. Customers appreciate this oven’s capacity for repeatable control of time, temperature, humidity and type of heat transfer.

The Reading Pretzel SPECTRUM OVEN® offers radiation, convection and conduction heat transfer options in a single modular design, making it ideally suited to extruded pretzels and snacks, baked snack crisps and pet treats. The SPECTRUM OVEN® features an easy-to-use system that gives the operator complete control of oven temperature, humidity, and product bake time. The addition of an optional Multi-Pass Dryer will increase oven speed, production throughput and process control.

Turnkey Production Systems

Our Thomas L. Green Hard & Soft Biscuit System creates sheeted and rotary moulded biscuits. For hard biscuits, the system offers a 3-Roll Sheeter, Gauge Rolls and a flexible Rotary Cutting Station. Soft biscuits are made on a Rotary Moulder designed to efficiently produce high definition, three dimensional biscuits, cookies and pet treats.

The Multi-Crisp Baked Snack System enables you to produce a variety of wheat, potato, multi-grain and corn masa flour crisps on one flexible system. The system can produce between 250-1000 kg/hr of finished product, depending on the number of oven sections after the dough sheeting equipment.

As suppliers of innovative industrial bakery equipment, Reading Bakery Systems would be happy to customize a solution for your bakery in South Africa that will meet your needs. Contact Hassan Harakeh at +971-56-6787885, call our USA headquarters in Robesonia, Pennsylvania at (01) 610-693-5816, or click here to find out more about our products.