The goal of Reading Bakery Systems is to help customers in Spain and around the world perfect their processes and their products with industrial baking equipment and complete turnkey systems that are specifically tailored to their needs.

Reading Bakery Systems provides innovative, high-quality systems for the production of crackers, biscuits, baked potato chips, cookies, pretzels, bread snacks, baked crisps, pet treats and more. No matter which type of snack foods you produce, we are ready to help you meet your process and product challenges.

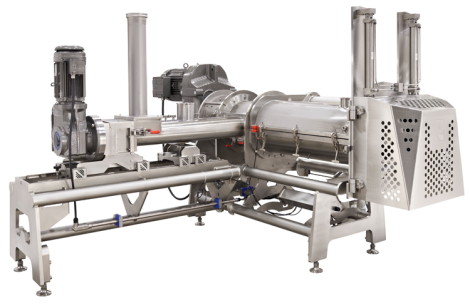

Mixing Equipment

Consider continuous mixing technology when you are interested in producing a more consistent dough and finished product. Our Exact Continuous Mixers come in many sizes, ranging from 50 to 10,000 kg/hour.

Models include the Exact EX Continuous Mixer, which is ideal for crackers, pretzels, pizza, sweet goods, pet treats and other wheat-based products, and the Exact HDX Continuous Mixer, which is ideal for products such as buns, breads, English muffins and similar products, and is designed to manufacture highly developed dough at low temperatures.

Dough Forming Equipment

Reading Bakery System’s Low Pressure Extruder enables you to create a variety of pretzel shapes, sticks, braids, filled sticks and bread snacks on one production line. Product changeover is as simple as exchanging one compression head and die for another one with a different shape.

The Thomas L. Green Rotary Moulder efficiently produces high definition, 3D rotary moulded snacks by pressing dough into a die roll. The interchangeable die roll can be supplied with segmented rings for simultaneous, multiple shape production.

For sheeted snacks, the Thomas L. Green Sheeter generates a consistent dough sheet, and the Gauging Stations ensure a gentle reduction in sheet thickness prior to shape forming. Scrapless geometric shapes and distinct shapes can be formed by the Rotary Cutting Station.

Baking Equipment

The biscuit, cookie and cracker industry has trusted Thomas L. Green ovens for more than 120 years. The PRISM OVEN is designed to enhance product consistency. Features include:

- Direct gas fired (DGF), convection, and Emithermic (radiant / convection) baking zones

- Better baking efficiency with uniform quality, color, taste and texture

- Repeatable control of time, temperature, humidity and type of heat transfer

When your product line involves pretzels, bread snacks, potato chips and other crisp baked snacks, the flexible Reading Pretzel SPECTRUM OVEN® offers the same flexibility as the PRISM OVEN and features:

- Radiation, convection and conduction heat transfer options

- Repeatable control of time, temperature, humidity and type of heat transfer

- Separate heating zones for more precise control

- Stainless steel interior construction

Turnkey Production Systems

RBS also manufactures and installs turnkey production systems featuring the latest technology that help customers efficiently and profitably produce baked snacks.

The modern, high volume Cracker System enables you to create straight sheeted, dual sheeted and laminated crackers. Sheeting systems can range from 600mm to 1.5m in width, and production volumes range from 200-5500 kg/hr depending on oven length, width and product type.

The Multi-Crisp Baked Snack System enables you to produce a variety of wheat, potato, multi-grain and corn masa flour crisps on one flexible system. The system can produce between 250-1000 kg/hr of finished product, depending on the number of oven sections after the dough sheeting equipment.

Learn how Reading Bakery Systems can meet your industrial bakery equipment needs in Spain by calling our European Sales Manager, Joe Pocevicius, at +31-615-510-789, our USA headquarters at (01) 610-693-5816, or click here to contact us online.