Features & Specifications

Additional Equipment Photos

See it in Action

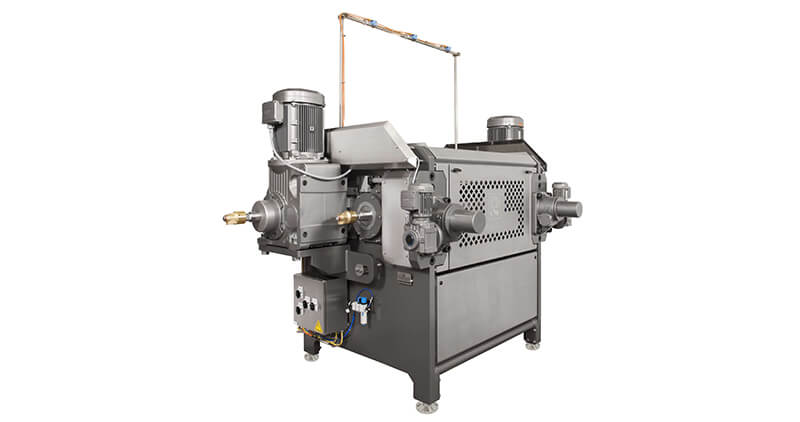

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

- Roll gap distance can be measured and monitored during production

- Separate direct drives for independent roll control

- Sheet thickness can be adjusted during production

- Easy access for maintenance and inspection

- Hopper level sensing for accurate hopper fill

Contact us for a full list of features and specifications.

Request more infoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Guards are designed to meet latest safety guidelines; electronically interlocked where appropriate

- Guard design allows for easy inspection during production

- Integrated roll scrapers

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

- Onboard touchscreen control interface

- Hopper level sensing

- Roll gap, roll speeds and conveyor speeds are all adjustable at the touchscreen control interface

- Automatic and motorized gap control