Features & Specifications

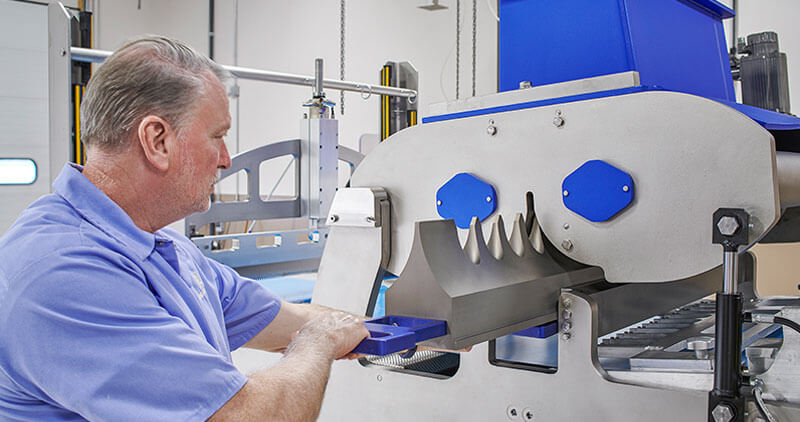

Additional Equipment Photos

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

- The recipe-driven linear servomotors provide an infinite number of cam profiles to control wire positioning, stroke length, and drop- and up-shoot

- Automatic feeding and separation is available for products that discharge onto paper

- Automatic operation controls ensure product quality and consistency and minimize operator interaction

- The hopper and roll assemblies are designed to be completely removed for sanitation and preventative maintenance procedures

- Custom designed die and wirecut assemblies include capabilities for two-dough products, co-extruded cookies, and encapsulated products

Contact us for a full list of features and specifications.

Request more infoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Light guards optimize operation safety during production and maximize access to machine components when necessary

- Operators can safely access all parts of the machine during changeovers and plant scheduled maintenance

- For easy maintenance, the machine has 50% less parts than a traditional frozen dough machines

- The hopper, roll assemblies, harp and wire frame are designed to be easily removed for sanitation and preventative maintenance procedures.

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

- Controls can be tied into an existing dough feeding system or a turn-key, automated, dough handling system can be supplied

- Servomotor based mechanisms offer flexibility and quick and easy changeovers.

- All adjustments to recipe and machinery are available via touchscreen. Servos control wire positioning, stroke length, and enable infinite cam profiles – stroke, wire height, drop and band-raise.