Features & Specifications

Additional Equipment Photos

See it in Action

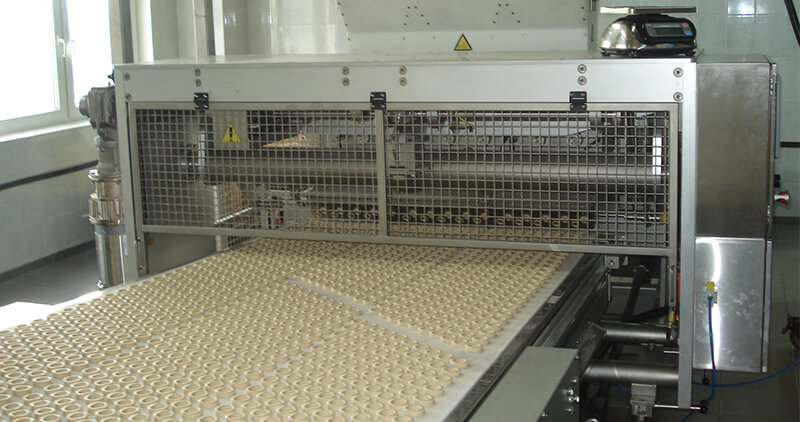

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

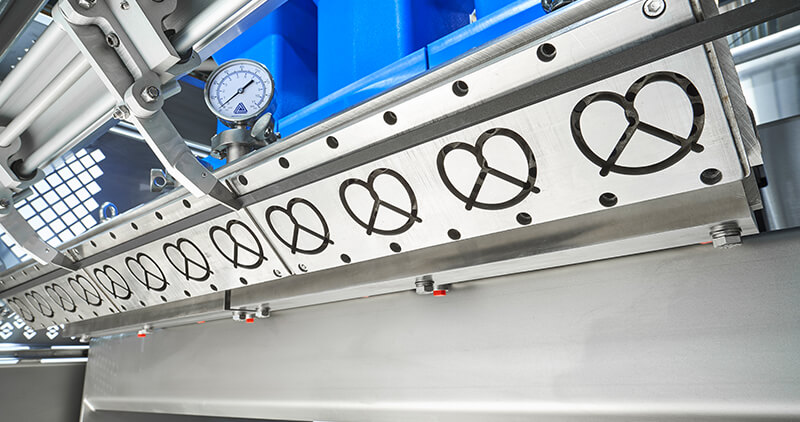

- Efficient and precise dough forming

- Consistent and accurate piece weights

- Quick, easy, low-cost product changeovers

- Bandcutter manually retracts for maintenance and sanitation

- Jacketed extrusion housings for temperature control

- Lightweight, seamless plastic hoppers for easy sanitation

- Bandcutter operates at up to 275 cuts per minute (cpm) or in cycle mode up to 50 cpm

- Available in 1 to 6 extrusion units at 13" (330 mm) or 15" (380 mm) per unit

- Capable of processing up to 3,000 pounds (1500 kilograms) of dough per hour

Contact us for a full list of features and specifications.

Request More InfoRBS equipment is designed and built to our SafeShield program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Automatic controls ensure operators are not exposed to moving parts

- Guards surrounding moving parts are electrically interlocked with the safety circuit

- Dough hopper is electrically interlocked with the safety circuit

- Disassembly of product contact components is simple and tool free

- Bandcutter blade can be automatically wiped during operation without stopping production

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

- Touchscreen control interface is mounted locally or in conjunction with other equipment

- Extrusion auger speeds and general dough flow are all individually controlled at the touchscreen control interface