Features & Specifications

Additional Equipment Photos

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

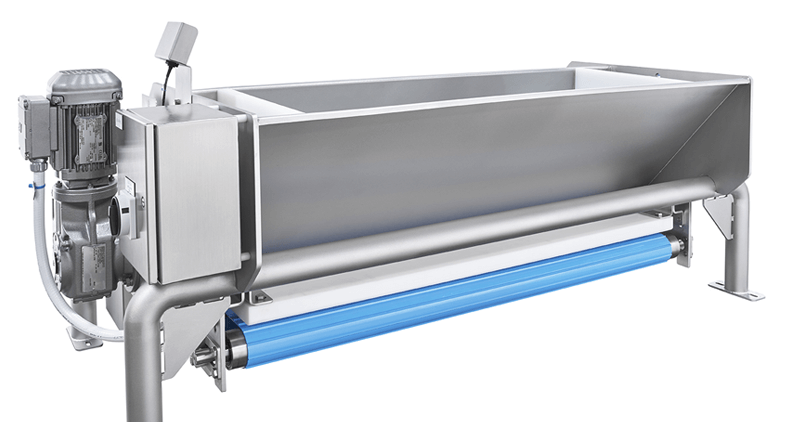

- Gravity fed hopper is designed for irregular toppings

- The adjustable height discharge roll allows the operator to modify the height between the hopper bottom and conveyor surface and accommodate the topping material size and flow characteristics

- Adjustable gate across the width of the roll balances the material flow from the reservoir

Contact us for a full list of features and specifications.

Request more infoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Hopper can be guarded to limit interaction during operation

- Stainless steel construction and use of thermoplastic belting for easy product release and cleaning

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production line running safely and efficiently.

- Electronic control of dispensing rate

- Local controls can be provided for stand-alone units