Features & Specifications

Additional Equipment Photos

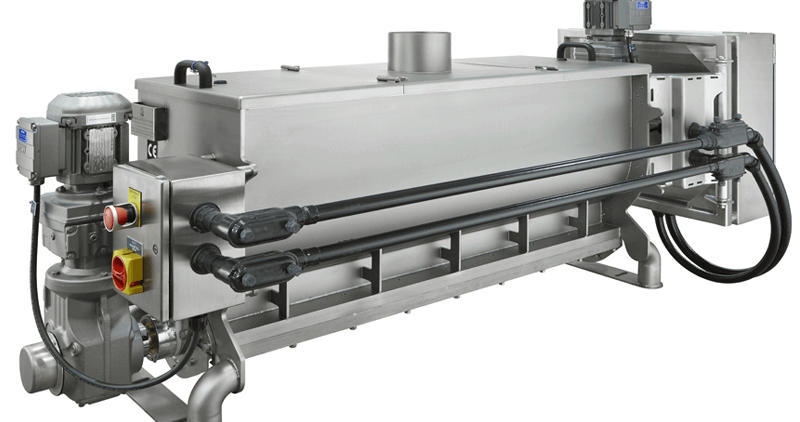

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

- Dispensing screen mesh size is product specific and screens can be easily changed for different topping production

- Material bridging and clumping are eliminated by the reservoir leveling mechanism

Contact us for a full list of features and specifications.

Request more infoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Guards are designed to meet the latest safety guidelines; electronically interlocked where appropriate

- Automatic process limits operator interaction during production

- [Optional] Access platform for safe operator access to the Dispenser during production

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

- Electronic control of dispensing rate

- Local controls can be provided for stand-alone units